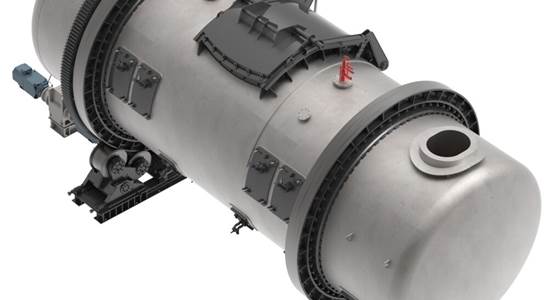

- Lowers energy consumption

- Decreases batch cycle time for more efficient refining

- Results in cleaner off-gases

- Improves scrap melting capacity (no need for additional melting furnaces)

- Increases flexibility by handling blister that contains impurities like arsenic or antimony