One-to-one replacement

Replacements fit in the same space as the old units, with no changes or modifications to the steelwork structure or chutes

OEM technology

To get the most out of your machine, it is important to use the right parts, understand how the machine works, and carry out preventive and predictive maintenance

Solutions

Turnkey packages with screen, media, parts, installation and

commissioning

Discovering your needs

Hewitt Robins has had a long history of screens in Europe and throughout North and Central America. The models it’s known for are Vibrex Incline Screens, Eliptex Horizontal Screens, Eliptex Pan and Grizzly Feeders, HDV Car Shakeouts, Trackside Car Shakeouts, Floatex Shakeouts, Vibrex VXX Scalping Screens, and Gyrex Screens. With its large installed base, there are many units in operation today.

Nordberg introduced heavy-duty mining screens with LM gear box exciters. Available with horizontal and multi-slope decks. These screens are equipped with features required in the toughest applications, including oversized cross beams, heavy lining systems, and gear box exciters that can easily change the counterweight settings. The DNA of these designs can be found in our equipment today. The photo shows a CVB screen with inclined deck, typically for the aggregate industry.

The screening division of the former Allis Chalmers Company was started in 1929 with the ”Style A” four-bearing screen. With nearly 100 years of screening experience, there is a large installed base of these screens throughout the world. The models it’s known for are Multi-Flo Banana Screens, SH and XH Ripl-Flo, Low-Head, Level-Flo, ST Ripl-Flo, Duo-Flo, Tripl-Flo, Low-Head Feeders, High Frequency Dewatering Screens, VFS, VHS, and VMOT.

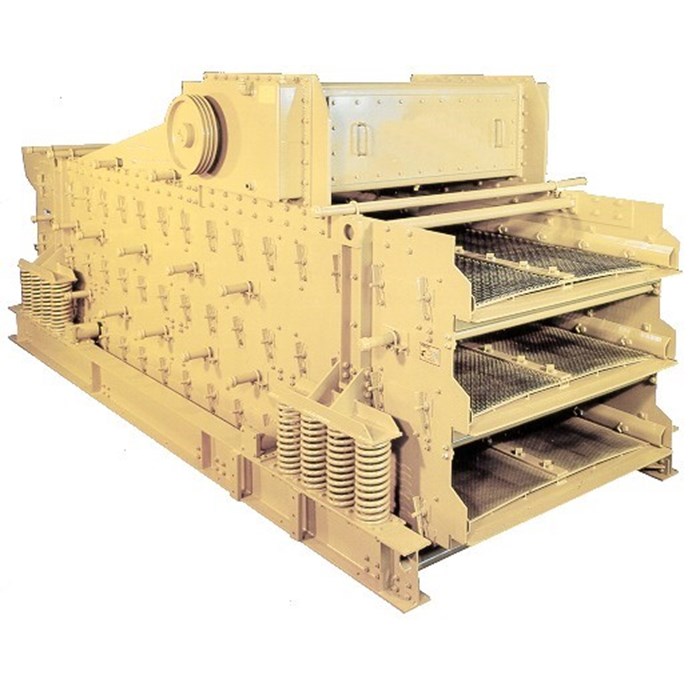

A wide range of robust circular motion screens and liner motion screen with self-synchronized mechanisms. Predominantly used in quarries and gravel pits. Deck frames from individual cross beams. Many options of deck frames for adapting the screens to any kind of screening media and a wide scope of applications. A well-known brand in North, West and Central Europe.

Originally known as Cleveland Wire Works, the company was founded back in 1872. In 1917 the first Hummer Electric Screen was introduced, marking the beginning of a new area for the company. W.S. Tyler has a large range of machines and a very large installed base throughout North, Central, and South America. The models it’s known for are Ty-Rocket SE and S Screens, CH70 Screens, Ty-Speed Screens, Ty-Rock Screens, and Ty-Hummer Screens.

In 1957 SECO introduced the first two-bearing incline screen, which is still the most popular style of screen in use today. SECO had a very large presence in the northeastern part of the US and Canada. Today people still like the robust machines, and there is a large installed base.