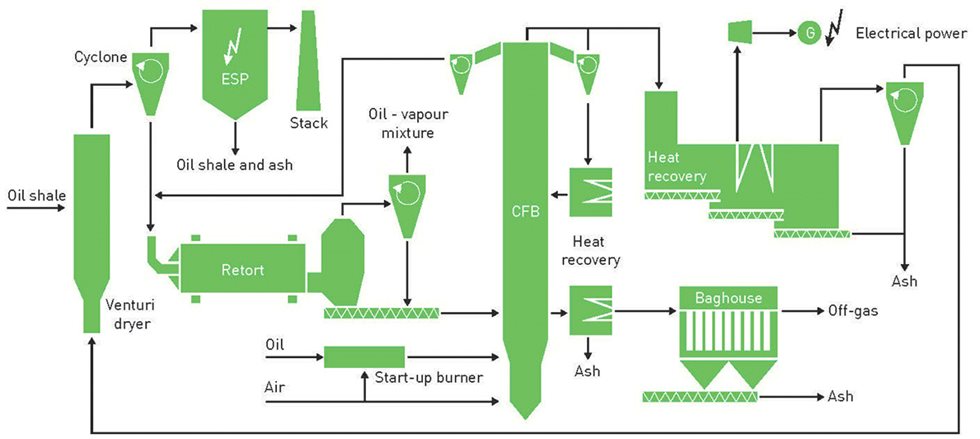

- Reduces total organic carbon left in the ash to zero, which allows for further utilization, for example in the cement industry or harmlessly landfilled for reclamation

- Uses excess heat for power production

- Gives you an energy efficiency-optimized process

- Limits emissions with EU and national standards

- Produces ~140 liter of shale oil per ton of raw oil shale treated