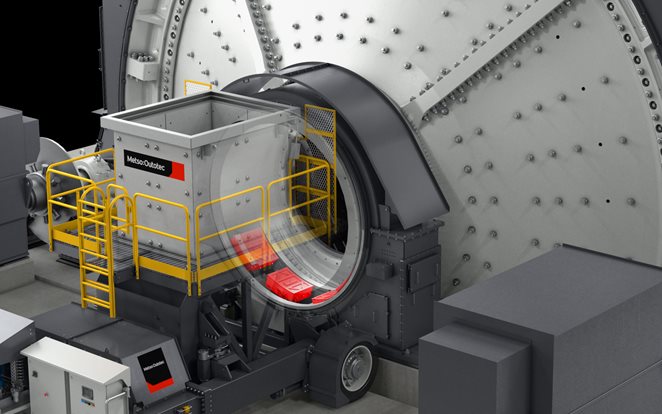

Improve equipment service life, maintenance, and process availability

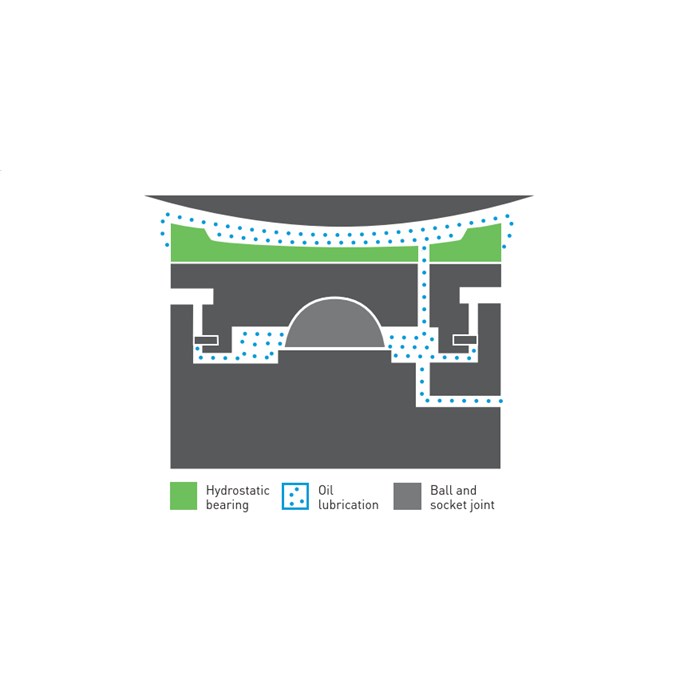

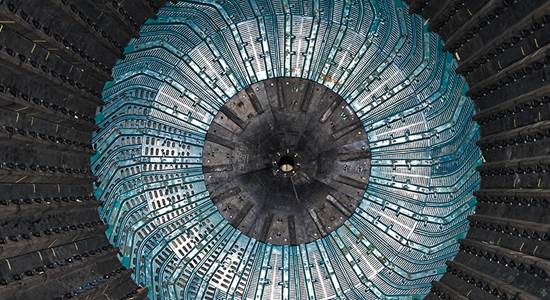

The Metso HSB upgrade is a modernization solution that helps maintain optimal performance of grinding mill equipment. The proven design improves the durability and serviceability of both radial and axial hydrostatic bearing pads and is the standard arrangement in many new Metso mill installations.

Existing bronze bearing pads are replaced with pads made from an advanced compound that significantly improves the maintenance, reliability, and sustainability of both radial and axial pads. The upgrade solution helps reduce lost production time due to bearing-pad surface damage and decreases operational and maintenance costs.

Reduce lost production time due to pad failures

Our upgrade solution is ideal for existing mill installations that suffer frequent production stoppages due to bearing pad failure. It has been developed primarily to eliminate the problem of failures associated with surface-to-surface contact resulting from journal defects, lock-charge startups, and hydraulic system failures. The upgrade incorporates significant design improvements that optimize hydrostatic loading under operating conditions where such failures are common, with advanced bearing pad materials that mold to the contour of the mill while maintaining strength, functionality, and reliability.

Reduced operational and maintenance costs

The self-lubricating characteristics of the arrangement can eliminate the need for an emergency accumulator system connected to the mill’s hydraulic circuit. Although disconnection of the existing accumulator system is not mandatory, doing so can significantly reduce operational and maintenance costs associated with servicing pressure vessels and complex hydraulic systems.

In many cases, the upgrade can enable a reduction in the thickness of the oil film at the bearing, which in turn reduces oil flows and the power consumption of the mill’s lubrication systems.

A customized solution for your mill

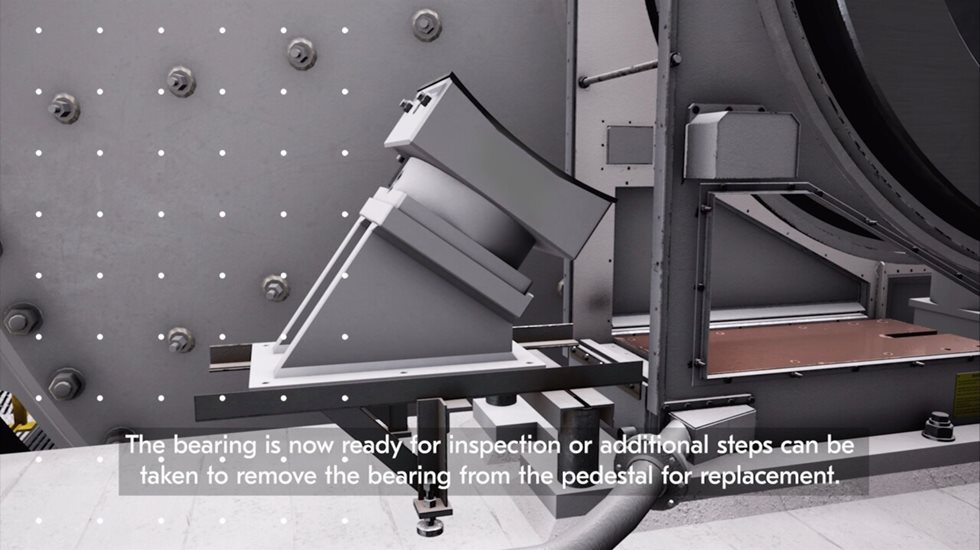

The Metso HSB upgrade is suitable for all Metso grinding mills that utilize a hydrostatic bearing configuration and can be supplied as radial pads, axial pads, or a complete kit with the optional configuration for disconnection of the accumulator system.

The upgrade solution includes:

- Custom-engineered HSB pads designed specifically for your application

- Specification of any necessary hydraulic system modifications

- New hydraulic set points to ensure safe mill operation

We can also support you with a complete range of installation and commissioning services that will keep downtime to a minimum and ensure a smooth start-up.