Why choose our grinding solutions?

Enhance circuit capacity to improve energy efficiency

Increase throughput and maximize production

Over 100 years of delivering reliable grinding solutions for a variety of applications

Applying the strictest standards and tolerances for guaranteed safety and reliability

Mills are originally sized for specific running conditions. Declining ore grades and increasing hardness makes supporting the market demand more challenging. As a result, improving throughput becomes a top priority.

It is, however, possible to increase throughput by maximizing the power draw of your existing mill without having to install additional equipment.

Our engineers will help identify your goals for increasing your grinding efficiency. Our grinding experts will then evaluate the current condition of your mill by conducting a mechanical study, providing recommendations, and supplying customized parts.

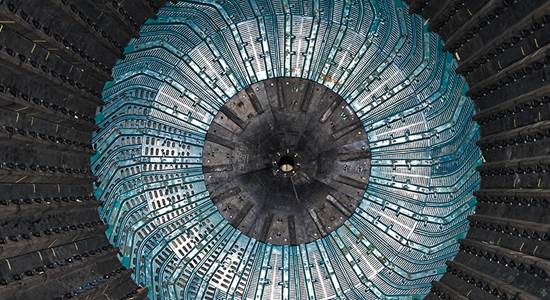

The study can include making adjustments to the mill power and mill speed, a review of the structural capacity of the mill rotating body, bearings, and foundation loads as well as a review of the drive components. A process study can also be performed should additional information be required.

Power draw increase can be achieved with one or more of the following:

- Increasing ball charge or volumetric loading, including a combination of replacing the feed and discharge end configurations and installing new drive components with higher mechanical ratings to sustain increased power draw

- Adjusting speed with additional teeth on the pinion or adding, for example, a VFD (variable frequency drive) and torque limiting coupling

- Re-configuring the discharge end by converting from an overflow system to a grate discharge system (specific to ball mills) or installing an AG/SAG mill curved pulp lifters for material to exit faster

We provide custom-design parts, technical support and installation for a turnkey solution.

As an OEM, we have been designing, manufacturing, and servicing grinding mills, parts, and retrofit solutions for over 150 years. With the use of detailed drawings and advanced engineering tools, we ensure that our solutions meet Metso’s strict standards and tolerances for safety, reliability, and quality.

With over 1500 global field service experts and an extensive network of engineers, from parts supply to installation, planned or emergency repairs, and life cycle services, we are here to support you.

We also offer various financial solutions such as long-term capex amortization, flexible payment terms, and value-added bundled packages to ensure our solutions match your business goals.