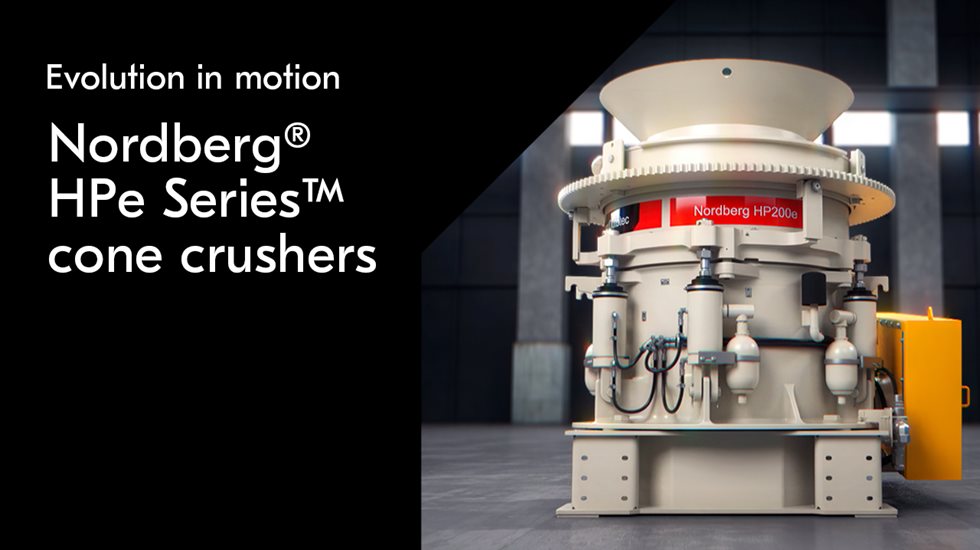

Evolution in performance

The kinematical crushing action and crusher chamber have been further developed and optimized resulting to significantly higher performance and grade of application flexibility.

- Perfect balance with kinematics, chambers, release force and power rating.

- Evolution in performance through more head motion, higher power, more force and new chambers.

Evolution in uptime

The crusher liners are installed without backing material. This will not only make the liner changes easier and shorten the breaks, but also has a positive impact on the environment and safety of the operators.

- Quicker, easier and safer liner change with no-backing liners.

- Extended liner life thanks to head anti-spin brake.

- Maximum performance and machine protection with an optional modern crusher automation IC70C.

- Enhanced machine protection with optional ring bounce monitoring feature.

Evolution in application coverage

Even wider application coverage than before -Extra coarse, New coarse, Sand chamber, Narrow fraction chamber. More abilities to optimize crusher behaviour and performance.

- Three alternative kinematics to choose from.

- Enhanced chamber designs and application specific chambers. Chamber Selection and Chamber Expert service support the selection of the optimal chamber.

- Alternative speeds.

Evolution in serviceability

- No-backing liners for quick, easier and safer liner change.

- Head anti-spin brake extends liner wear life.

- Enhanced tramp release cylinder mounting.

- New feed cone lifting tool, for safe lifting and handling.

Reliable cone crusher wear and spare parts enable stable production without unexpected downtime. We have a wide cone crusher spare parts offering for Metso, Nordberg®, and Symons™ models, as well as many crushers made by other manufacturers. The parts are available as standard or tailor-made according to your application requirements. We support you from over 150 locations globally from recommended parts lists to installation to upgrades and beyond.

Get the most out of your crushing circuit. Whether you are looking to minimize downtime, increase capacity, lower your cost per ton, improve sustainability, or meet specific size-reduction requirements – Metso can support you. We have Over 1,500 field technicians providing the knowledge you need and a rapid response time.