Versatile applications

Flotation froth pumping. Phosphate and apatite washing plants. Calcium carbonate upgrading plants. Mixing and distribution units. Cement plants.

Increased efficiency

More efficient pumping at higher capacities and a smooth operation, free from pulsations caused by air locking.

Robust parts

Extra-long wear life. Parts in different materials are fully interchangeable and can be combined.

Less maintenance

No submerged stuffing box, bearings or shaft seals. Design ensures minimum maintenance and eliminates any requirement for water flushing.

The concept behind a froth pump is to avoid pumping air and to separate as much air as possible from the slurry before it reaches the pump impeller.

The vertical froth pumps utilize the same principle as hydrocyclone separation where air is separated from the slurry in a vortex created by the impeller rotation and the tangential inlet to the pump’s conical sump.

This results in more efficient pumping at higher capacities and a smooth operation, free from pulsations caused by air locking.

Sala VF froth pumps are often used in applications that involve handling of air entrained slurries, such as flotation froth in base metal concentrators, phosphate and apatite washing plants and calcium carbonate upgrading plants.

They can also be utilized as a mixing and distribution unit, where dry powder has to be mixed with water, as well as with cement in ready mixed concrete and for grouting and injection mixing.

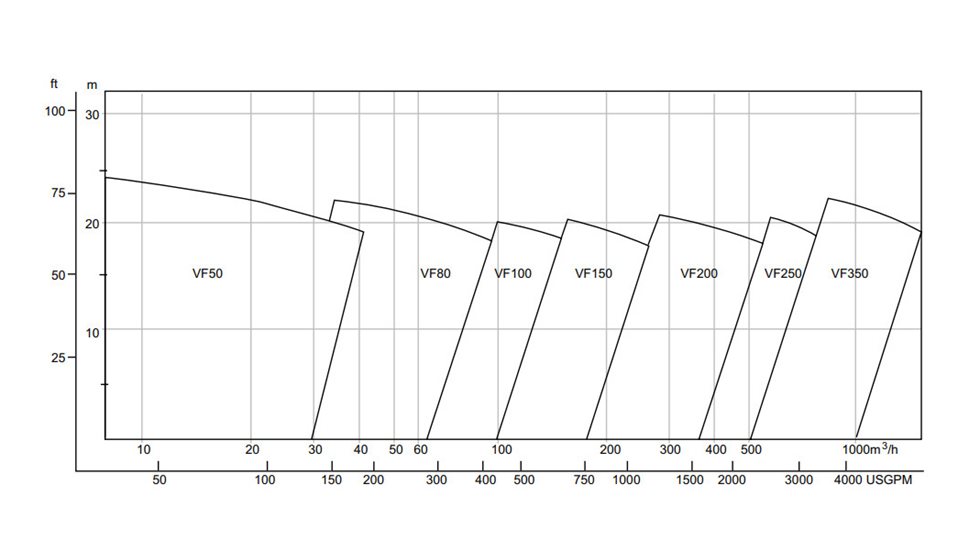

- Flow rates to 1 500 m³/h – 6 600 USGPM

- Heads up to 20 m – 65 ft

Typical applications

- Flotation froth pumping

- Phosphate and apatite washing plants

- Calcium carbonate upgrading plants

- Mixing and distribution units

- Cement plants

-

Integrated unit for layout flexibility

-

Smooth operation of the open vortex created in the sump and vertical “wet end” inlet prevents air locking

-

Cantilever design does not require submerged bearings or shaft seals

-

Bearing assembly with double protection sealing arrangement to prevent ingress of slurry

-

Wear parts are available in a variety of different materials

-

Simplified maintenance

Standard pumps are supplied with parts in wear resistant Natural Rubber or High Chrome iron alloy, with a nominal hardness of 600 BHN. Other materials are also available.

The wear parts have large material sections for extra-long wear life and are designed for the toughest applications.

Parts in different materials are fully interchangeable and can be combined for optimum life.

The heavy-duty pump shaft is a cantilever design, hanging below the bearing housing. There are no submerged stuffing box, bearings or shaft seals. This design ensures minimum maintenance and eliminates any requirement for water flushing.

Impeller clearance is maintained by external axial adjustment of the shaft/bearing assembly. Bearings have double protection seals against the ingress of slurry.

The casing on the Sala VF froth pump is supported by a beam. The beam is either lowered by hand or a hydraulic jack, depending on the pump size. The beam can be turned out so that the “wet end” parts can be accessed by a lifting device.

Sala VF froth pumps technical specifications

{{decodeHtmlEntities(field.label)}} |

|---|