Maximize productivity

Modular, flexible and high capacity solutions for optimal processing

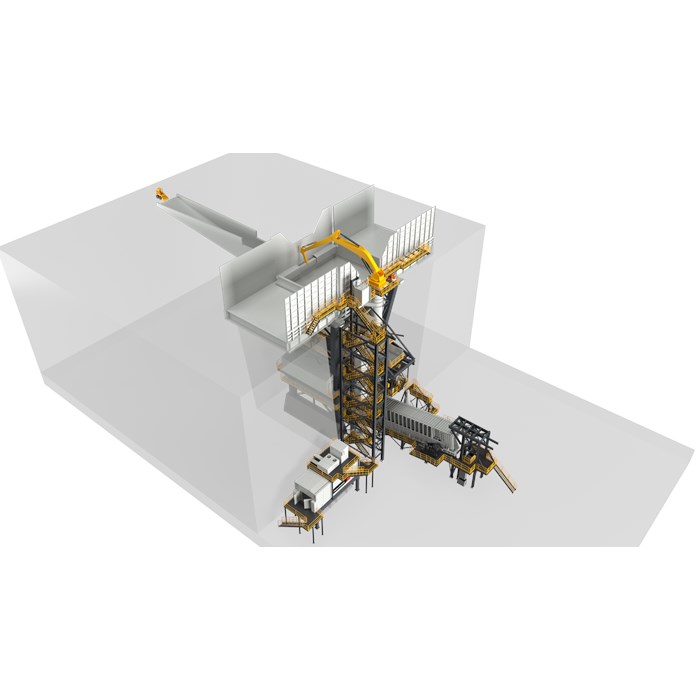

Minimal civil works and foundations

Reduced tensile forces and concrete foundation requirements

Improved maintainability and safety

Designed for easy access and safe maintenance

Minimized environmental impact

Utilize dust mitigation systems to reduce dust emissions

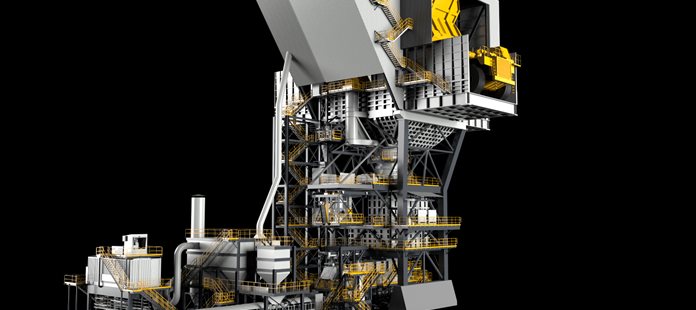

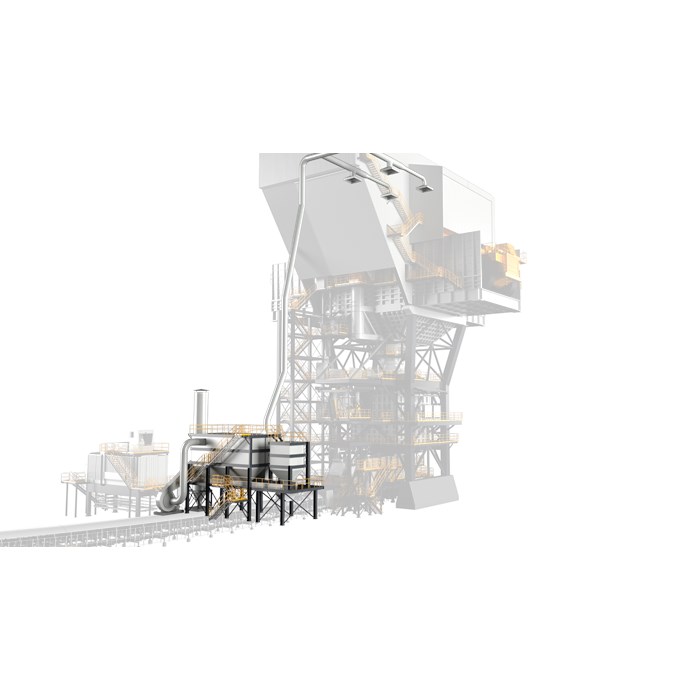

The Foresight™ SMPG station design in terms of capacity are driven by a few factors:

- Truck sizes

- Average hourly production requirement in tons

- The run-of-mine (ROM) feed particle size distribution

- Required maximum product size as P80 or P95

With this knowledge, the feed hopper, vault, truck ramps, crusher and discharge feeder can be selected accordingly.

The Foresight™ SMPG station determines mobility by the ability and associated effort level required for future crushing plant relocation or assembly outside of the crusher pocket. Plants that do not require relocation can be mounted on foundations and be equipped with bridge cranes rather than jib cranes as they offer a better operability while enabling the addition of roof covers and side cladding to the bridge crane structure.

Establishing mobility requirements determines:

- Structure modules and relocation

- Pontoon OR foundation

- Crane type and roof

The Foresight™ SMPG station configuration options for flow control address feeder equipment choice to meet material characteristics in terms of flowability. With the correct feeding equipment choice, the plant can maximize availability and productivity.

There are different feed areas and equipment to be considered:

- Station feed: Direct / Apron feeder

- Discharge feed: Conveyor, apron feeder or SMPG feeder

- Measurement: Rocker breaker, Magnet

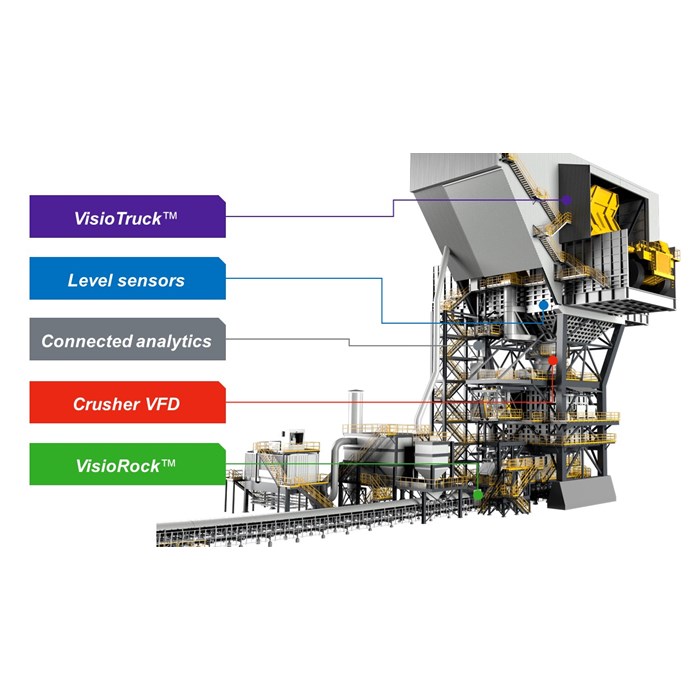

Metso offers various configuration options for Process Control to boost productivity. It covers the areas of the electrical design and supply in terms of power, motor and automation infrastructure and varying battery limits according to customers and project requirements.

Further process control can be performed through our SmartStation technology and global performance center support. Find the different areas fo process control below:

- Electrical and automation

- SmartStation

- Connected analytics

The dust control configuration area allows matching regulatory, operational and material requirements with the correct suppression and/or collection equipment.

The parts that make up a dust control configuration for the SMPG station are:

- Water spray or dry fog

- Encapsulation

- Dedusting

Metso’s Foresight™ SMPG has the highest inbuilt safety, accessibility, and maintainability of semi-mobile primary gyratory plants on the market.

Our service teams support, operate and maintain crushing plants and conveying equipment around the globe and their feedback is continuously reflected in our design improvements. This enables Metso to match plant design and on-site performance, in operation and maintenance, to deliver the tons on a continuous basis, at highest availability.

Find below what makes us up such a safe, accessible and maintainable solution:

- Eccentric cart and pin gate

- Rotable top shell

- Loader access and ancillaries