The most complete product range on the market to maximize output and safety of your conveyor operations.

Dedicated to keeping your operation as productive and profitable as possible.

Durable conveyor parts designed for long component life.

Smart, simple design that makes parts efficient, robust and maintenance friendly.

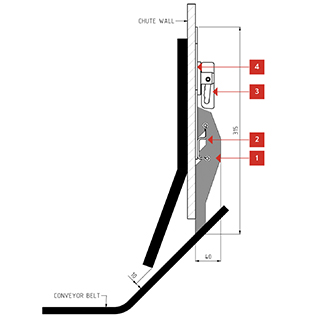

WAMskirt sealing system properties and features

Material:

- White iron (check)

- Rubber or polyurethane

- Steel

Installation:

Heavy duty (Steel cord belts) mining applications

Standard, customize or retrofit:

The standard system features a narrow installation height, but modules are fully customizable to specific dimensions and liner configurations. WAMskirt can also be easily adapted to different mounting systems, making it a straightforward retrofit in most skirting environments.

WAMskirt technical specifications

{{decodeHtmlEntities(field.label)}} |

|---|

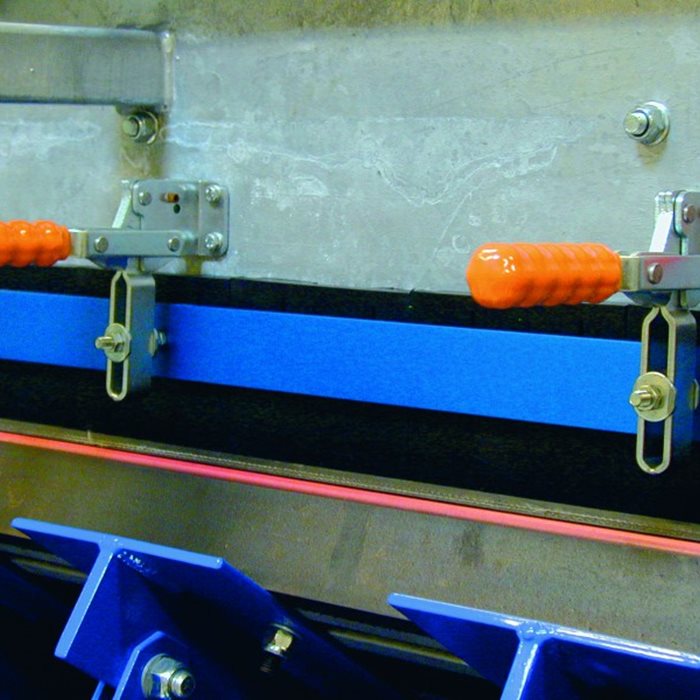

Trellex Clamp-On properties and features

Material:

- Galvanized steel

- Aluminium

- Steel/Plastic

- Foam polyerethane PU

Hardness 4: 85 ±5 Shore A

Density: 1.03 g/cm3

Color: Black

Trellex Clamp-On technical specifications

{{decodeHtmlEntities(field.label)}} |

|---|

Trellex Snap-On properties and features

Material:

- EPDM rubber RU

- Galvanized steel

Hardness: 60 +/-5 Shore A

Density: 1.16 g/cm3

Color: Black

Trellex Snap-On technical specifications

{{decodeHtmlEntities(field.label)}} |

|---|

Trellex Wearliner properties and features

Material:

- Rubber RU

- Steel (t = 5 mm)

RU Hardness: 60 Shore A

Color: Black

Trellex Wearliner technical specifications

{{decodeHtmlEntities(field.label)}} |

|---|

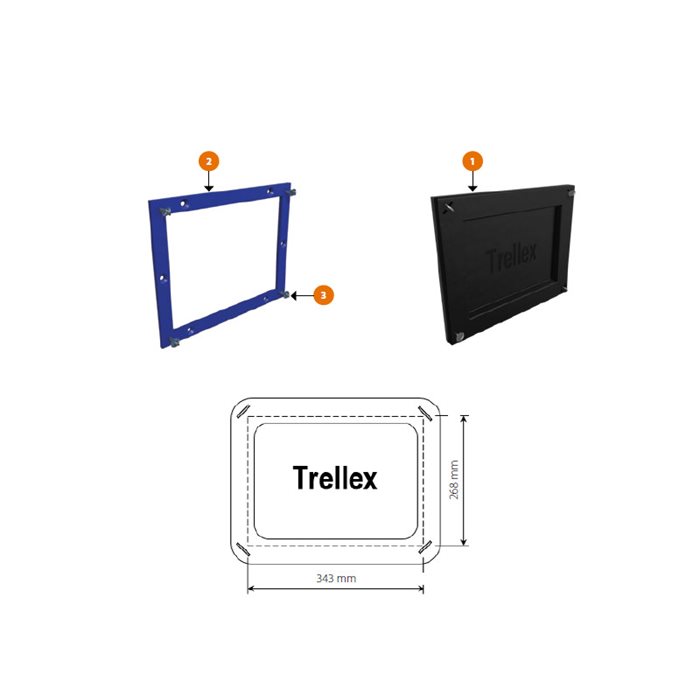

Trellex Inspection Hatch properties and features

Material:

- Foam PU

- Powder dip-coated steel

PU Hardness: 44 Shore A

Color: Black

Dimensions: Hatch 400x325x30 mm

Trellex Inspection Hatch technical specifications

{{decodeHtmlEntities(field.label)}} |

|---|