Inspections catch issues early for less unplanned stoppages which carry more risks than properly planned maintenance breaks

Identifying problems before they escalate ensures higher equipment availability

By adjusting flushed glands, this allows operations to avoid excessive water usage

Getting fast & accurate information about the condition of your pumps allows for improved operation & maximized equipment lifetime

Catch issues earlier for highest equipment reliability

Undetected issues can lead to breakdowns and unplanned service work, significantly increasing repair costs and production losses.

Get fast, accurate information about the condition of your equipment, recommendations for maintenance and improved operation with our systematic pump inspections.

The information provided will assist in minimizing unscheduled downtime and reduce long-term operating expenses. Our specialists can also recommend service agreements and spare parts.

Sustainability advantage

Pumps that are running smoothly will use their energy requirements most efficiently. Regular inspections can identify problems and give you a chance to solve the issue, thus reducing waste and getting the most from your equipment.

A full inspection with the pump operating, this is a quick way to understand your pumps overall condition for peace of mind.

Inspection offering:

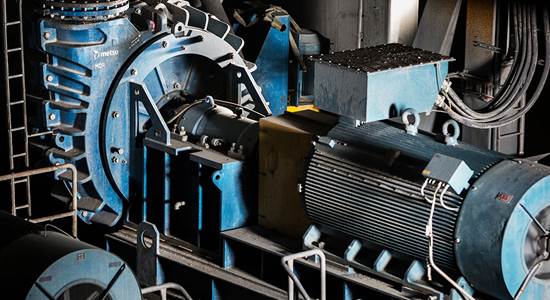

- Visual inspection of the general installation, pump, motor, drive and system

- Catch safety hazards, underperforming pumps and general observations

- Wet end: leaks around inlet and outlet connections

- Shaft seal: gland performance and adjustments as required

- Bearing assembly: temperature and vibration

- Historical data helps predict pump performance over time

- Detailed future inspections recommended if needed

Full inspection of a non-operating, rotable spare or stocked pump. This can be undertaken at the installed location or in a service workshop. This allows you to maximized pump availability through a more detailed service inspection with additional adjustments and services. Includes the visual and vitals with extras, such as:

Inspection offering:

- OEM inspection with guards removed

- Impeller axial clearance adjustment as required

- Inspection of wear and spare parts

- Inspection of drive components

- Historical data helps predict wear and spare parts life and service intervals over time

This is a full visual, vitals and mechanical inspections. Additional inspections, measurements and services are performed, thus further maximizing pump performance and equipment longevity.

Inspection offering:

- Customizable reporting including measurements and action recommendations

- Modernization and upgrade recommendations

- Spare part audit and availability check

- Plant optimization: Pump performance checked against the PumpDim sizing and process data