Produce based on customer demand

Producing manufactured sand to order according to customers’ specifications makes your process and raw material usage more efficient.

Turn waste stockpiles into profitable product

Manufacturing sand from waste stockpiles is an ideal way to produce a high-quality commercial product that has a market and high demand.

Save in transport and logistics costs

The distance to market is reduced dramatically because m sand is not sourced from distant shorelines or riverbanks.

High and stable quality for improved price

Unlike with natural sand, you have full control over end product quality. Eliminate reject. Produce sand with optimum shape and gradation to justify a premium price.

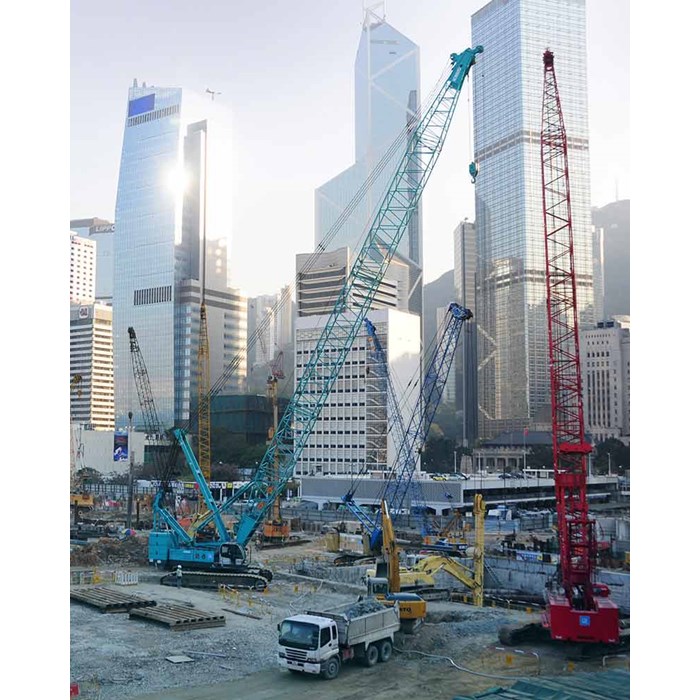

Rapid urbanization driving demand

Sand is a key ingredient in concrete, cement and asphalt. As the cities around the world continue to grow, the demand for sand is growing along with them.

Environmental protection a priority

Sand has traditionally been obtained from natural sources. However, new tighter environmental regulations are being put in place to protect sources of natural sand. In many cases sourcing sand from riverbanks and shorelines has been banned completely.

Distance means time and money

The depletion of natural sand resources is a major concern, and in areas where demand is highest, there are fewer and fewer sustainable sources. As a result, sand has to be transported over greater distances and the price has increased.

Production based on demand

Producing artificial sand to order makes your raw material usage more efficient.

High and stable quality

Unlike with natural sand, you have full control over end-product quality. Eliminate reject production and get the best return on your product.

Make more from less

Produce sand with exactly the right shape and gradation. Your customers need less cement in their concrete to achieve optimum quality, strength and structural integrity, helping you justify a premium price.

Savings in transport costs

The distance to market is reduced dramatically because the sand isn’t sourced from distant shorelines or river banks.

Turn waste into product

Produce a high-quality commercial product that is in high demand.

The quality of artificial sand can be adjusted and optimized, which reduces the amount of sand needed in making concrete and asphalt.

- Ideal shaping (cubical or spherical)

- Gradation according to customer wishes

- Fine particles without silt, clay or shale

1. Sand making

In crushed aggregates production, up to 30% (rock dependent) of materials acquired from the bedrock are reduced to sizes smaller than 4 mm, meaning they end up as waste. These stockpiles are a perfect feed for the production of manufactured sand.

2. Crushing and screening

Efficient crushing and screening shape the feed material to uniform consistency, precise form and gradation.

3. Air classification

Dry classification reduces the amount of dust and superfines, which helps to meet strict specifications and improve end product quality.

4. Sand

The final end product is manufactured sand that is superior in quality to natural sand, giving great returns on a raw material that was previously waste.

Your unused or rejected aggregate materials can be turned into profitable product with the help of reliable and robust technologies.

Metso offers complete crushing and separation solutions for greenfield sites as well as solutions that can be incorporated into existing plants.

Depending on your requirements, there are several alternatives for sand manufacturing, all designed to produce well graded, high-quality end product.