Lower risks with proven know-how

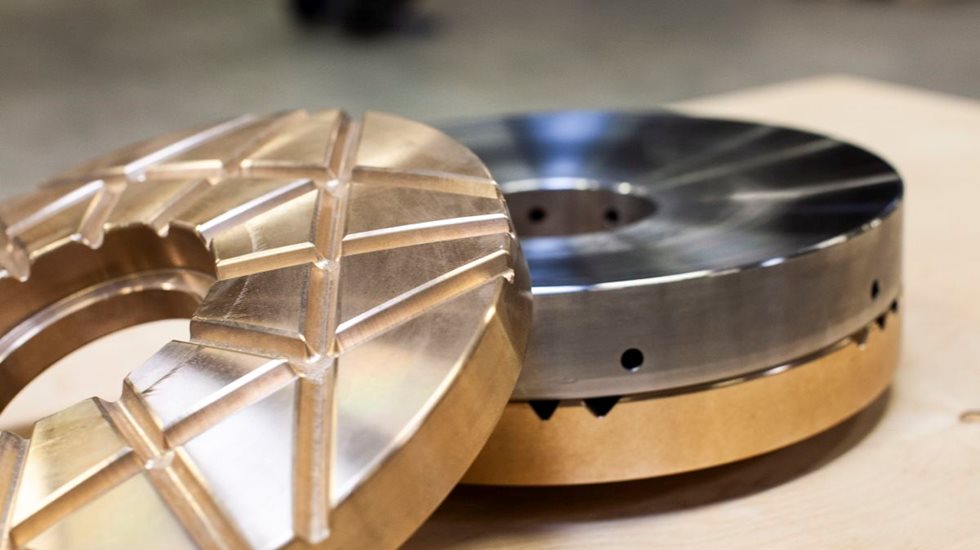

For us, quality is not limited to parts’ features, but it means also our readiness to provide extended support when needed. Non-OEM part suppliers might have the capability to provide a certain missing part to the crusher, but is it of the right material? The exact right design? These things can’t be guaranteed, and the risk of malfunction in operation or additional servicing can start to climb if a sub-optimal supplier is used. We combined our expertise and heritage as the pioneer in many crusher technologies into a premium series of crusher parts for non-Metso crushers, the Contender™ Series. These parts are made to ensure an exact fit and they can be counted on to perform.

Another thing to consider is the warranty. If the part doesn’t live up to expectations, an OEM manufacturer like Metso has a strong warranty program in place. With a warranty, the risk of unplanned costs for the crusher operator is minimized, and the performance is followed up on in a timely manner. Also, a partner like us with a strong footprint and background has more capabilities available to ensure that the right part, no matter which one it is, is in stock when needed. We have large inventories quickly accessible and are not limited to certain parts only.

It is an economical decision to choose a partner, not only a supplier

One of the main advantages of centralizing the maintenance activities of multi-brand crushers, including parts and services, is cost savings. Instead of dealing with multiple interfaces, aggregate producers can have one point of contact to take care of everything. That is our mentality, to provide a partner solution to our customers instead of just parts and products. It makes the planning a lot easier and makes the service more efficient, which helps in increasing the uptime and thus – as time is money – increase the profitability.