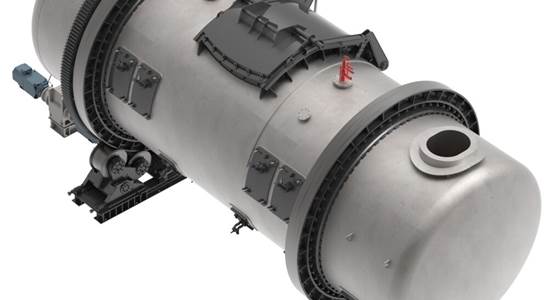

Effectively cast dore anodes at high capacity with Metso's Outotec Dore Anode Casting.

- Results in a very accurate casting weight

- Allows high-capacity casting

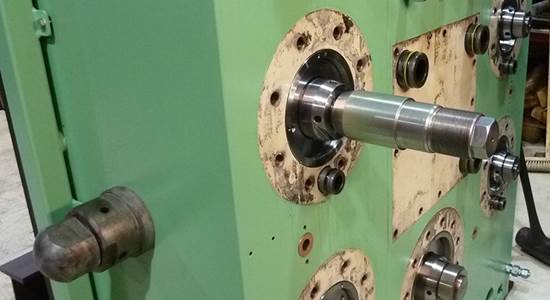

- Offers a modular construction for easy serviceability

- Includes a high level of automation

- Provides automatic anode handling and packing