Unique know-how and leading processes to help you reach your sustainability targets

The cleaning formula is non-hazardous and non-corrosive

Flushing is performed during production in under an hour

Cleaning is a fundamental aspect of maintenance to control the risk of contamination, quality and safety

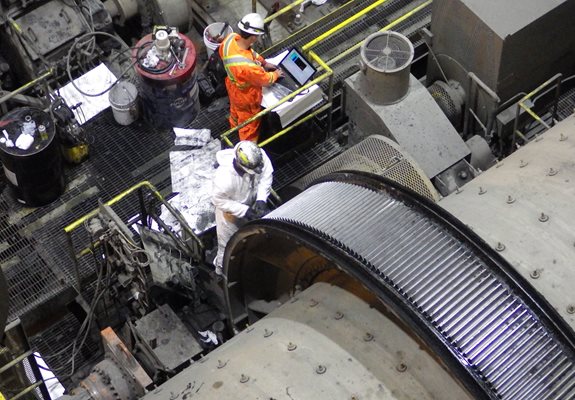

Over 20 years’ experience in providing large girth gear cleaning services

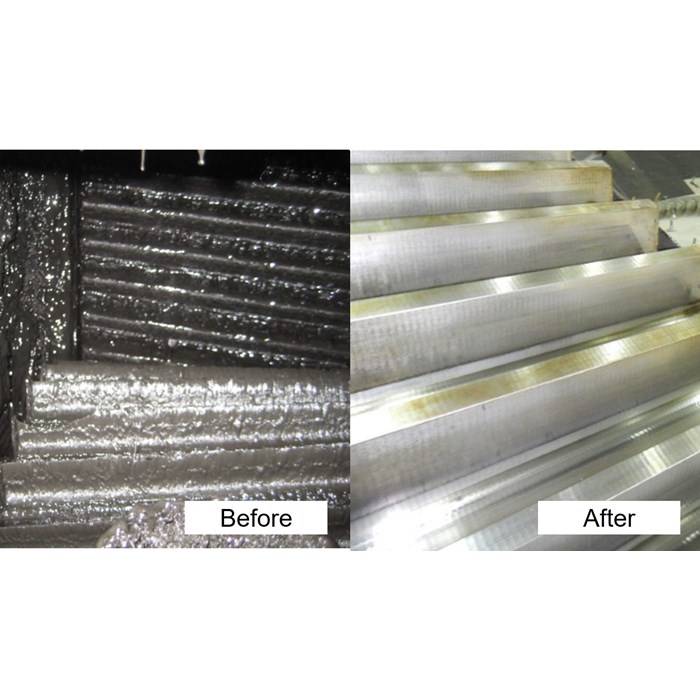

- Removes contamination and lubrication build-up

- Performed in under an hour minimizing downtime

- Cleaning performed during production

- Non-corrosive

- Non-hazardous

Cleaning is fundamental

The Cleansolv High Flash EP formulation is designed to remove contamination and lubricant buildup on girth gears and pinions prior to inspection. This is accomplished by flushing the girth gear when the mill is about to stop, during grind out minimizing downtime.

The actual time of flushing a gear set is under an hour. There is no need to wipe the gear teeth down or rinse after, to remove residue as in Magnetic Particle or Dye penetrative inspections; if using ASTM E2905 inspection method.

The GF460EP Flushing Lubricant is an exceptional Flushing Lubricant for open gear flushing applications; designed to remove contamination and lubricant build-up on girth gears and pinions prior to inspection or any related maintenance procedures.

Gear engineer gear teeth analysis

Gear Engineers worldwide use visual interpretation (AGMA 1010-F14) as the standard used to analyze gear tooth condition, such as contact patterns, alignment and wear patterns.