- Low power consumption

- Mechanical simplicity

- Continuous operation

- Low maintenance

- No operator required

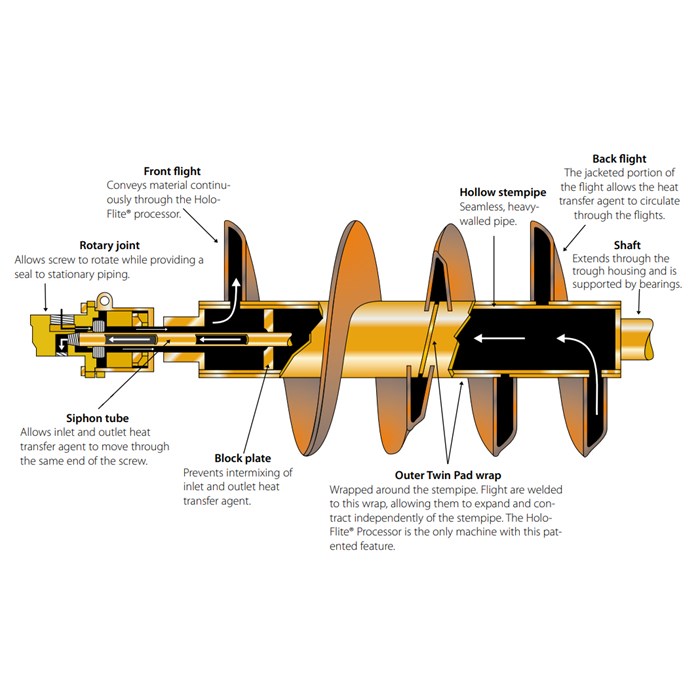

- Particles are indirectly heated or cooled via the hollow flights, shaft, and trough

- Heat transfer is achieved by using water, steam, or thermal oil

- Heat transfer process can be easily controlled to achieve the best results

- Extreme expansion and contraction of the screw is easily handled by the Holo-Flites patented twin pad design that allows for successful operation up to 1,200 degree Celsius for product cooling

Product system offering/ ancillary equipment offering

- Standalone unit for heating, drying, cooler

- Thermal fluid heating system

- Wet scrubbing for off-gas handling system

- Dust collection for off-gas handling system

- Cooler water heat exchanger

- Feed and takeaway systems

- Rotary Air Locks

- PLC/ HMI controls

- Structural Steel

- Commissioning & Process Audit services

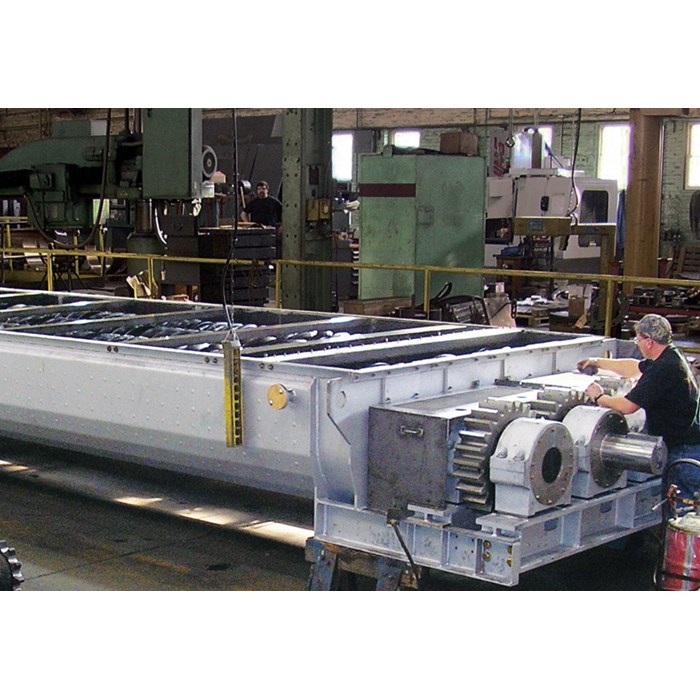

Mastering the design and manufacture of indirect heat exchanger systems

Metso maintains the original engineering drawings, quality standards, and process design for all Holo-Flites® manufactured over the past sixty years.

- Western Precipitation Holo-Flite®

- Joy Manufacturing Holo-Flite®

- Denver Holo-Flite®

- Denver-Sala Holo-Flite®

- Denver-Svedala Holo-Flite®

- Svedala Holo-Flite®

Wide range of process applications

- Cooling calcium carbonate, iron oxides, fly ash/ incinerator ash, limestone

- Drying alumina, carbon black, sodium, plastics, chloride, molybdenum, waste sludge and coal

- Heating limestone filler, petroleum coke, petro-chemicals, sand

Applicable industries

-

- Petro-Chemical processing

- Industrial power applications

- Mineral and Coal applications

- Food Processing

- Plastic and Polymer applications

- Waste sludge

Continuous conveying

Particles are heated or cooled as they come into contact with the surfaces of the hollow flights, shaft(s) and trough.

The product is continuously conveyed by the rotating screws along the jacketed trough.