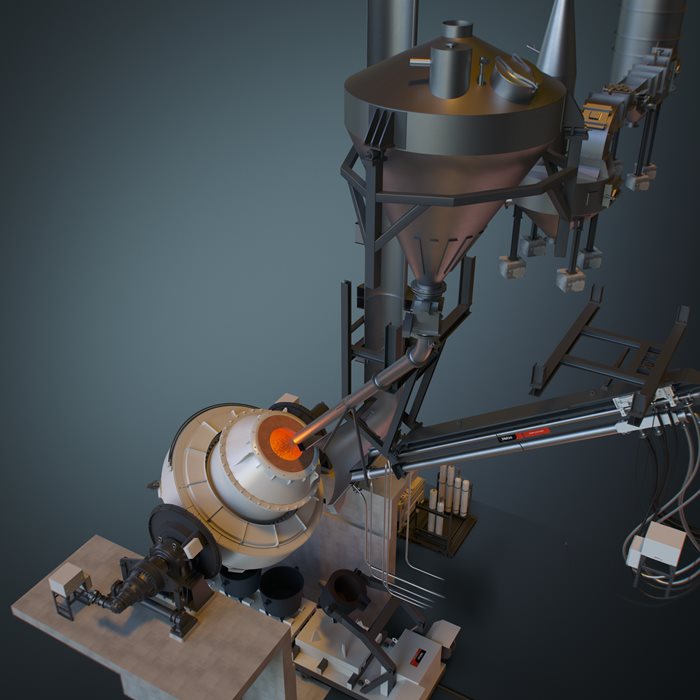

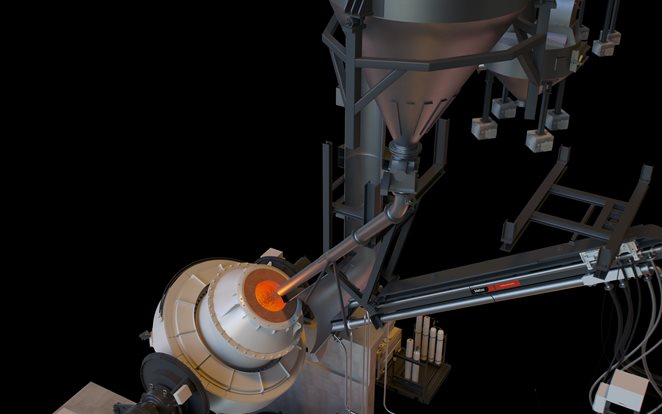

Metso’s Outotec® Kaldo L Furnace - which is the 4th generation Top Blown Rotary Converter - utilizes the vast experience from previous TBRCs in the steel and the nonferrous industries. Kaldo L is a heavy-duty furnace with smooth movement, and is designed to achieve maximum efficiency for melting and processing of several different materials. The technology is supported from processes and equipment in symbiosis. The system is a part of Metso’s Planet Positive portfolio, which highlights offerings that contribute to a more sustainable environment.

Metso's Outotec Kaldo L Furnace is a flexible solution for smelting and converting various primary and secondary raw materials such as concentrates, copper scrap, e-waste, and precious metals anode slimes. It is equipped with advanced charging and off-gas systems, thus allowing a very compact plant layout and operational flexibility.

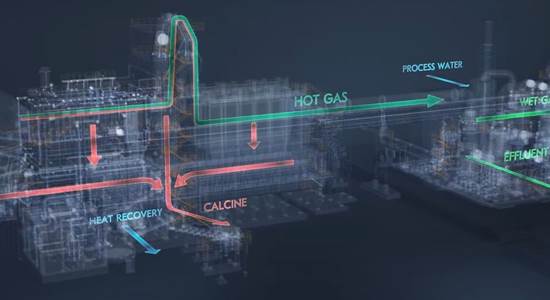

The process with smelting, reducing, and converting can be performed in a single vessel.

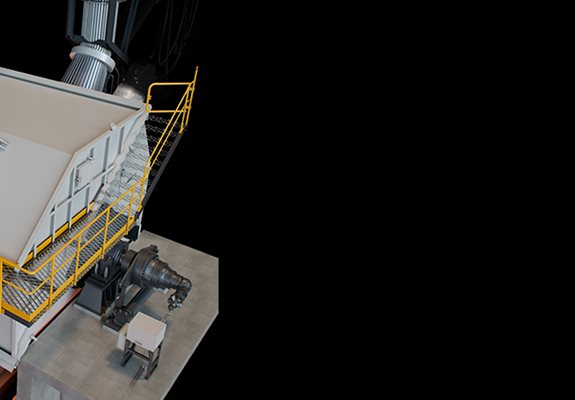

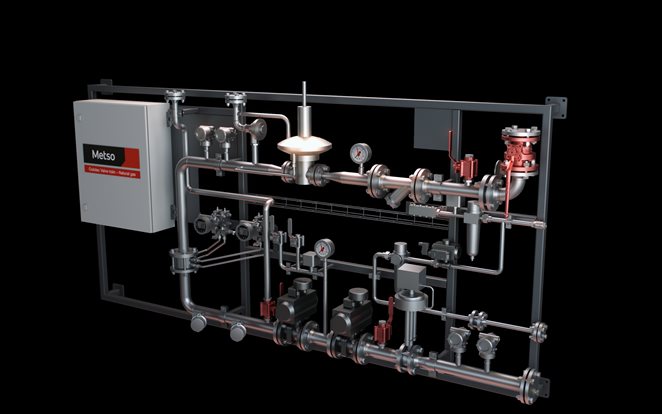

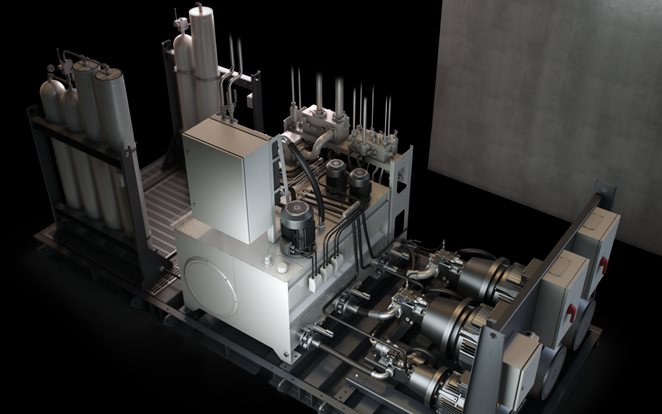

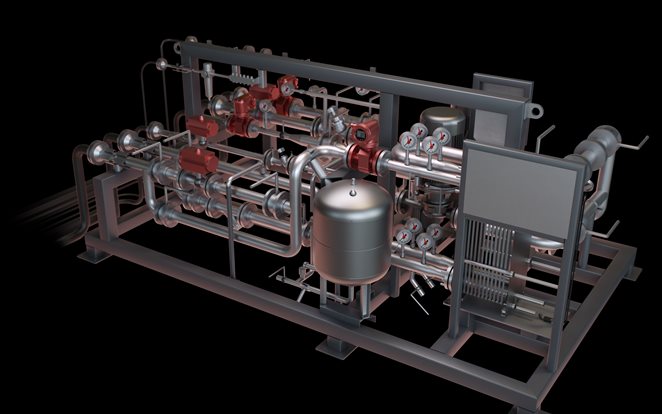

The system is fully encapsulated by a furnace casing, thus facilitating ventilation of the whole section, including the ladle car below the furnace. Stray emissions are prevented, resulting in a safe working environment. An advanced hydraulic system allows smooth and safe control of any movement. The heating and converting processes are performed by introducing water-cooled lances mounted in lance wagons with a hydraulic drive. A Multi-Purpose Utility Lance can also be introduced for temperature control and refractory wear measurement. The cooling system is equipped with a safety system to prevent water leakages into the vessel. In case of a system malfunction, an internal energy accumulator will automatically move lances out from the vessel and allow a tilting of the vessel to empty the melt into ladles. Material is introduced to the vessel by one of several systems, depending on the process. Process control from the operator panel and control room with an advisor system is possible to assist the operator.

Metso’s Outotec Kaldo has been successfully used in the precious metals, copper, and lead processing industries for decades and represents the best available TBRC technology for this purpose. Metso has continuously developed the Kaldo Furnace since the 1970s and has substantial references globally. A Pilot plant TBRC Kaldo L is available for tests where customers can verify and validate materials and processes before making important decisions.