Easy operation and high efficiency

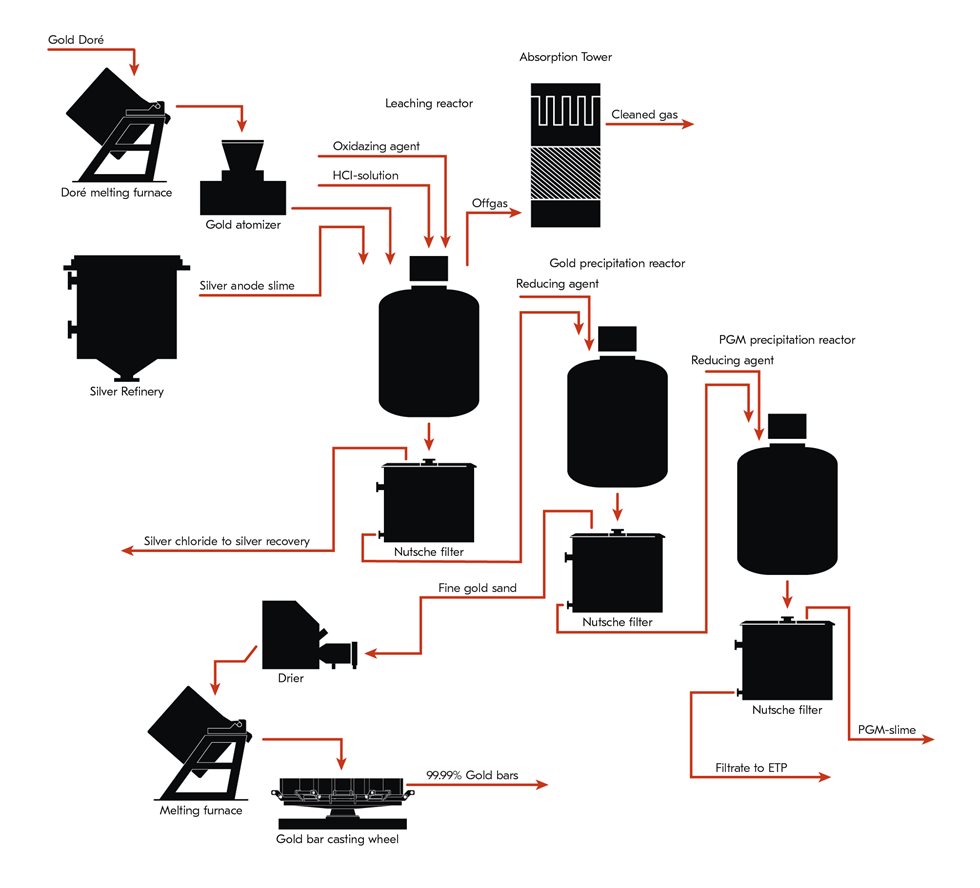

Metso's Outotec Gold Refinery is the result of more than 30 years’ experience in developing robust and cost-effective solutions for precious metals recovery and refining. The process has been successfully applied worldwide in installations with annual gold refining capacities from 1 to 50 tons. The gold refinery is purely hydrometallurgical, i.e. an oxidative leaching of gold bullions or concentrates followed by selective precipitation of fine gold. In contrast to conventional pyrometallurgical chlorination of crude bullion with subsequent electrolytic refining (Miller and Wohlwill processes), our technology offers very high direct recovery, short process time, low inventory of gold bound in the process and ensures good and safe working environment. The process produces fine gold and separates valuable impurities such as platinum group metals (PGM) and silver for recovery and further refining.

Atomization of gold doré

The feed material received from gold cyanidation plants is high-grade gold bullion bars. Before being processed at hydrometallurgical operation the bars are melted and atomized to fine powder. This offers the benefits of a much larger contact surface area available for the chemical attack and increased reaction rate of the process. Shorter residence time allows in turn to reduce the volume of leaching reactors.

Gold precipitation, filtration and drying

The major part of the dissolved gold is selectively precipitated by addition of a reducing agent to the solution in the precipitation reactor. The precipitate of fine gold sand is filtrated, carefully washed and then dried. The filtrate is pumped to the second precipitation reactor where reduction of the remaining dissolved gold takes place. Gold received after the second precipitation has lower quality and is recycled to the leaching tank for refining. This way the purity of the precipitated fine gold is maintained at a high level. The filtrate received after the second gold precipitation is sent for recovery of PGMs.

Casting and granulation

The dried gold sand is melted in a furnace and cast into bars. Depending on the capacity of the Gold Refinery installation, casting of 400 troy ounces (~12 kg) fine gold bars is done either manually by using a removable crucible and a casting table or by using a Metso Gold Bar Casting Wheel. The gold bars are then cooled in a water bath. Alternatively, gold granules can be produced.

Gas cleaning

The off-gases from the leaching and precipitation reactors are scrubbed in a gas cleaning system to absorb the fumes of acidic gases. The gas cleaning system consists of a washing tower, a condenser, and a circulation tank. The treatment of the off-gases also ensures the high recovery of precious metals.

Effluent treatment

The filtrate received after PGMs recovery undergoes an additional treatment step to ensure an essentially precious metals free solution. The solution received from the recovery of the precious metals is sent to the wastewater treatment.

From single pieces of equipment to full turnkey plant delivery

All the features of the Metso's Outotec Gold Refinery are designed to increase the efficiency of the process and the amount of gold recovered, decrease manual work and improve working environment. The modular design makes it easy to scale the solution for your desired capacity. Metso offers comprehensive technologies and equipment packages for the whole production chain from the mine to refined metal. With extensive research facilities and resources, we ensure that the latest advances in your chosen technology are continuously available when needed, and when they benefit you most. The core of our design lies in the environmentally sustainable technology, which enables economically feasible silver refining technology.

Metso services improve your process performance

Through Metso global network of service centers in more than 25 countries we provide lifecycle services from spare parts, maintenance and technical services to modernizations and O&M agreements. Our service experts provide punctual spare parts logistics maintenance and training, as well as assessment and consulting services that generate a competitive advantage for you. We can tailor services efficiently to your specific needs, when considering the necessary operational and maintenance services already from the beginning of the project. As a trusted service partner, Metso ensures an optimized operation for the entire lifetime of your plant. Obtaining all spare parts and maintenance from the same organization as process and equipment design ensures that your plant runs optimally. We make sure that you receive only the highest quality parts, consumables and upgrades that can be seamlessly integrated into your plant.