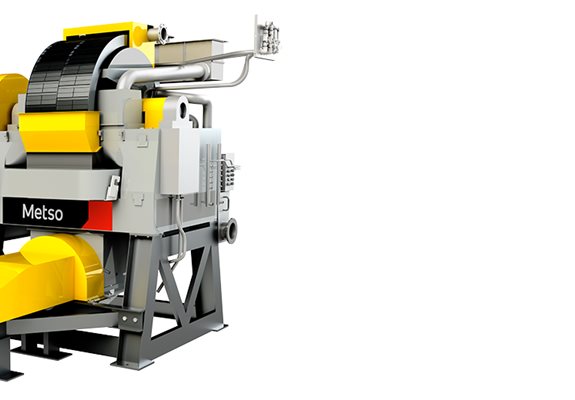

Vertical ring configuration

The ring is arranged in a vertical orientation as opposed to a traditional Jones-type WHIMS, which uses a horizontal carousel. The vertical nature of the carousel allows for reverse flushing, where magnetics flushing in the opposite direction of the feed allows strongly magnetic and/or coarse particles to be removed without having to pass through the full depth of the matrix volume. In addition, the magnetics flushing is accomplished near the top of rotation, a location with a low stray magnetic field to reduce any residual grip on the magnetic particles. The end result is high availability due to minimized matrix plugging.

Pulsation and slurry bath

An actuated diaphragm provides pulsation in the separation zone to assist the separation performance by agitating the slurry and keeping particles in a loose state, minimizing entrapment. This mechanism also maximizes the particle accumulation (trapping) on all sides of the rod matrix, creating more usable surface area for magnetics collection. A further benefit is to reduce particle momentum, which aids in particle capture by the applied magnetic force. This leads to improved fine particle collection and separation.

Rod matrix

The SLon VPHGMS utilizes a filamentary matrix constructed of steel rods to accommodate various size ranges of feeds. The rods are oriented perpendicular to the applied magnetic field to enable optimum magnetic force to be achieved while minimizing the risk for entrapment of particles, when compared to grooved plates, randomly positioned filaments (wool), or expanded metal sheets.