What signs indicate that you are not optimizing your crusher's ultimate potential?

-

Are you producing enough of some specific end-product fraction (desired yield vs. non-saleable product)?

-

Is your cost-per-ton at the desired level?

-

Is the wear pattern of your crushing chamber smooth and straight?

-

Is your crusher’s power consumption steady (no power spikes)?

-

Is the scrap percentage of your current wears low?

If you respond ‘no’ to any of the questions above, altering the chamber design can yield favorable results for your crushing operation.

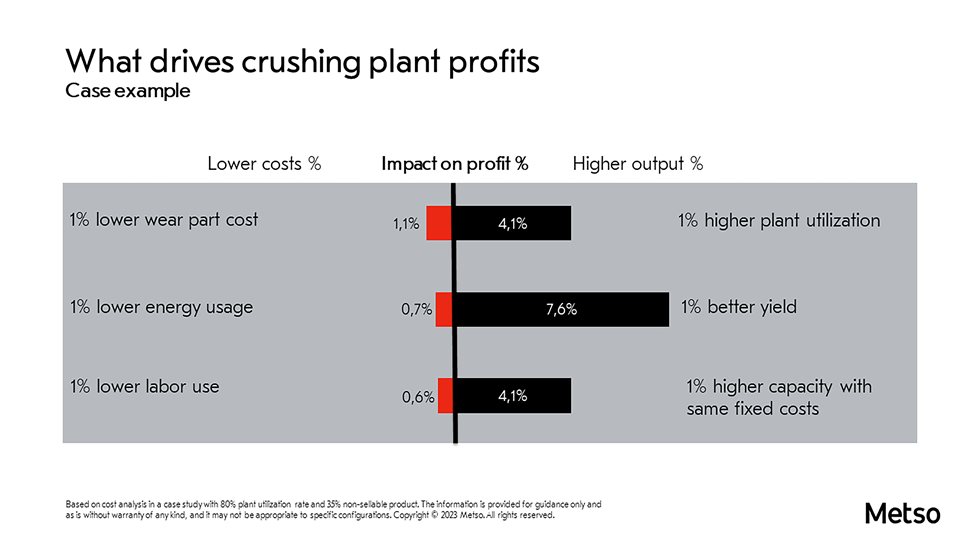

When discussing wear parts selection with contractors and quarry operators, it often comes as a surprise to many that these components can significantly influence the overall performance and profitability of a crusher and the entire plant. The crusher serves as the core of the plant's productivity, and as such, it must operate at its peak efficiency. Although wear parts typically account for less than 10% of a plant's operating costs in a crushing and screening circuit, the right selection of crusher wear parts can wield a substantial impact on profitability. In fact, choosing crusher wear parts based on their influence on productivity and, consequently, profitability, is a more prudent business approach than solely considering the upfront cost of these parts.