Sustainable mining practices

As a key provider of the technology or solutions for processing the minerals needed for the energy transition and given how energy intensive the mining industry is, Metso Outotec’s approach to innovation can have a substantial impact. We have an essential role to play in supporting our customers in their sustainability efforts by developing minerals and metals processing practices that have a lower impact on the environment. This includes the development of energy-efficient equipment, fostering the use of renewable energy sources, recycling and reusing materials as well as reducing waste and emissions. In addition, the industry must focus on responsible water management, minimizing water waste and reducing the intake of fresh water. Not forgetting the utmost license to operate: safety, which is the highest priority for our customers.

Sustainable minerals and hydrometallurgical processes rely on R&D and innovations. Metso Outotec targets that 100% of the R&D project spend is with projects that have sustainability targets and we are already very close to our 100% objective in our R&D pipeline.

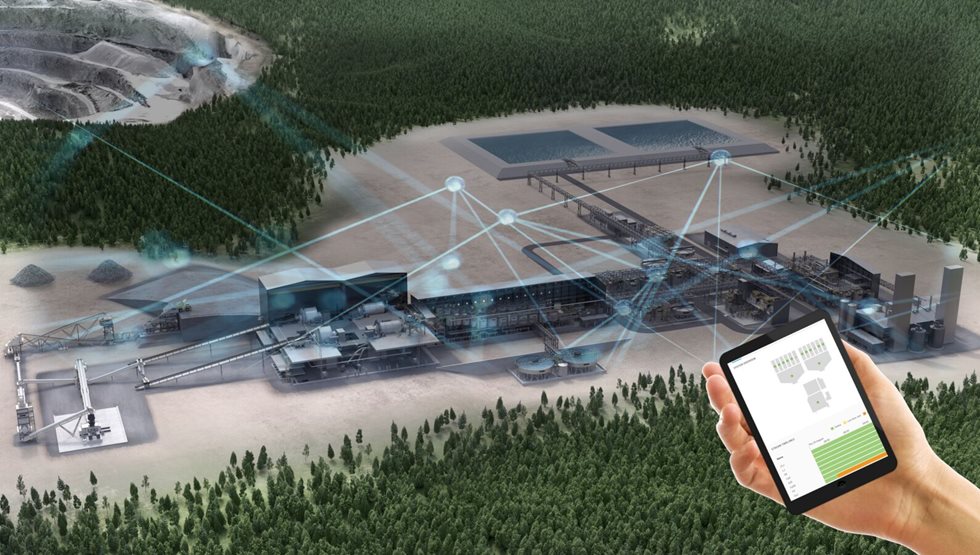

Advanced technology and digitalization

Digital solutions play an important part in our customers’ sustainable productivity strategies. The minerals industry is already using advanced technologies that include artificial intelligence, machine learning and autonomous equipment to improve energy, carbon and water efficiency, reduce costs and increase safety. Large mining customers already use real-time sensors, big data analytics and digital twins to improve equipment efficiency, accelerate decision-making, monitor and optimize processes, improve maintenance practice and reduce risks.

Digital solutions can help with many things such as extracting the full value from low grade ore bodies or waste stockpiles, designing and operating an asset with full life cycle in mind, converting tailings into valuable products and services, as well as building more efficient and sustainable water treatment solutions. To make this happen, miners actively collaborate with industry partners, such as OEMs, to develop the next generation of sensors to maximize data collection and help minimizing environmental footprint. Metso Outotec has a long history of providing automation solutions, including analyzers for particle size and elemental measurement in slurry and on belts, as well as intelligent instruments. Our sensors and analyzers gather data that is used in our higher-level automation systems and advanced process control systems to optimize the operation of unit equipment, circuits, and entire processes. Geminex™, our metallurgical digital twin, and Metrics, our connected analytics platform, are a key part of our digital offering. These solutions are designed to address the growing demand for digital process optimization and artificial intelligence-driven performance and reliability improvement in modern mines.