This article was originally published in Global Mining Review’s January/February 2024 issue.

In the dynamic realm of mining, sustainability and efficiency emerge as pivotal concerns. The imperative for environmentally responsible practices and the persistent quest for heightened productivity prompt mining companies to explore inventive solutions. Metso is positioned at the forefront of this transformative industry as global leader in sustainable minerals and metals processing technologies. Our approach encompasses tailings and water-driven solutions, offering a comprehensive strategy to tackle the challenges and opportunities confronting modern mining. This article delves into four key facets of our strategy:

- Embracing higher pressures and bigger filters

- Leveraging digital technologies for water management

- The economic benefits of tailings processing solutions

- Service solutions for tailings

Embracing higher pressures and bigger filters

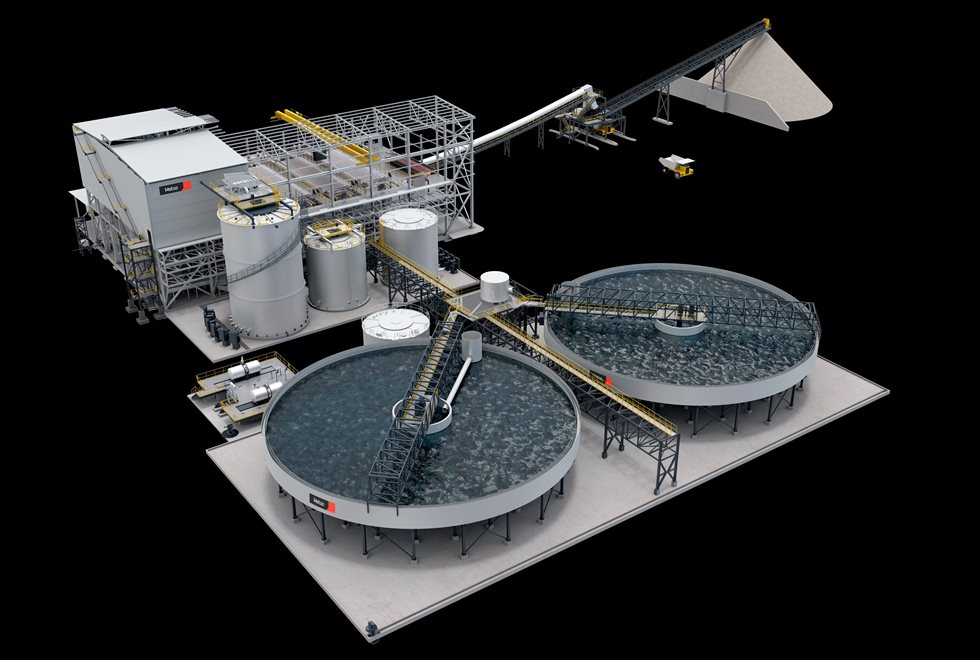

As mines grow, the demand for more efficient dewatering solutions becomes apparent. Metso has innovatively addressed the challenges posed by higher pressures and the need for larger filters. A significant contribution is our high-pressure filtration technology, allowing for the efficient dewatering of tailings at notably higher pressures than conventional methods. This method minimizes the volume of slurry that needs storage, contributing to a more sustainable approach to tailings.

Metso utilizes filtration equipment, including filter presses and pressure filters, designed to meet the rigorous demands of modern mining operations. This not only enhances operational efficiency but also contributes to a reduction in the environmental footprint associated with tailings disposal. Our larger filters, such as the Larox® FFP filtration technology, enable mining companies to process greater volumes of material, increasing overall productivity. Moreover, our expertise in filtration technology ensures that these larger filters are reliable and efficient, minimizing downtime and maintenance costs.

The combination of high-pressure filtration and larger filters aligns seamlessly with our commitment to sustainability by reducing the amount of water in the tailings and the volume of storage required. This translates to decreased environmental impact and lower long-term costs for mining companies.