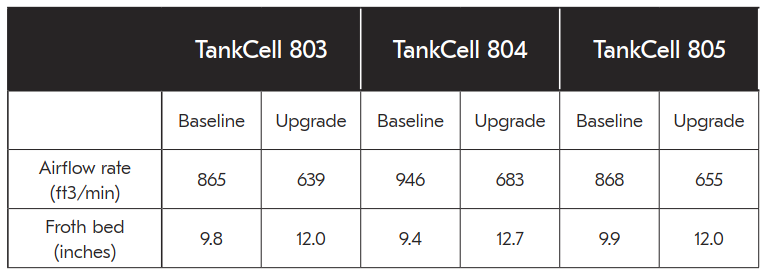

The Kennecott Copperton concentrator is a 150 ktpd Copper-Molybdenum operation located just outside Salt Lake City, Utah. The rougher scavenger circuit consists of four rows of five Metso Outotec TankCell®300 each. The first two cells operate as roughers and the latter three as scavengers.

CHALLENGE

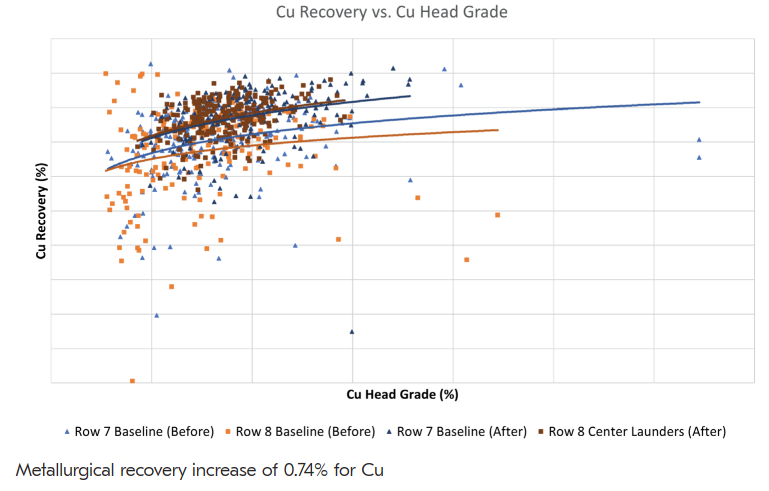

After the commissioning of the new flotation circuit, the coarse particle flotation response on the large forced air cells was not optimal compared to the smaller cells. This was attributed to the larger froth zone characteristics of the bigger cells.

SOLUTION

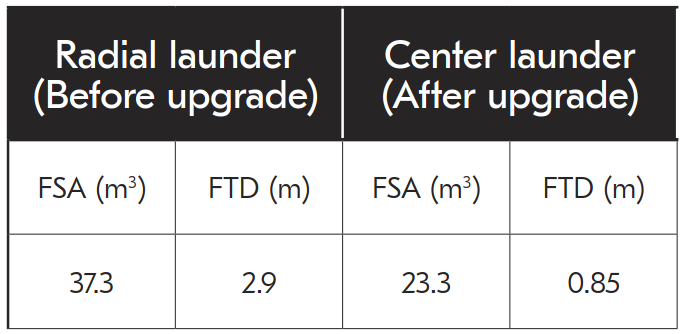

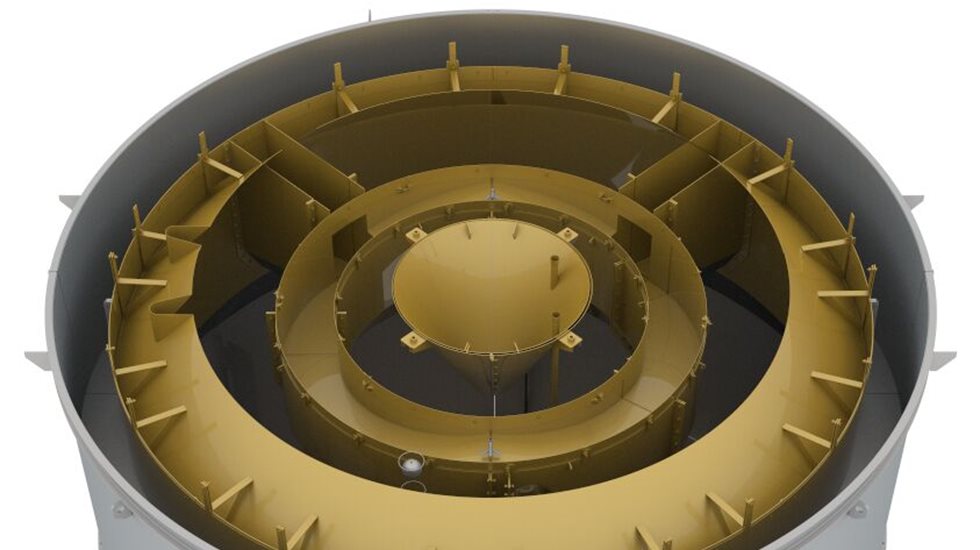

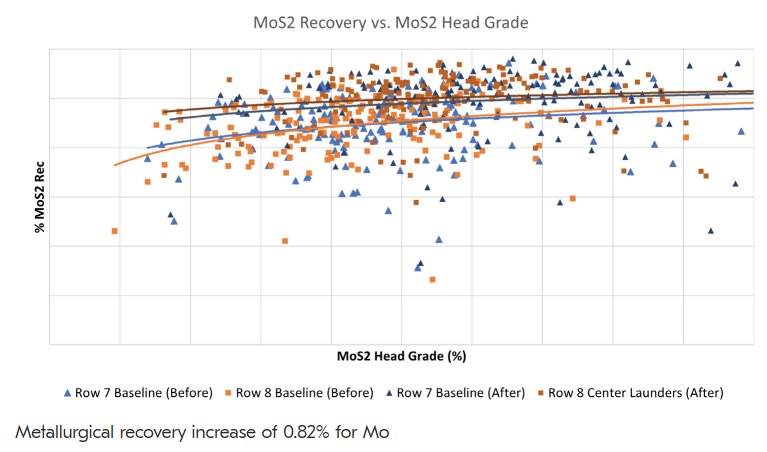

A site assessment was recommended to evaluate possible solutions. Metso Outotec recommended an upgrade of the radial froth launders in the scavenger TC-300 tank cells to center launders based on the findings of the assessment.