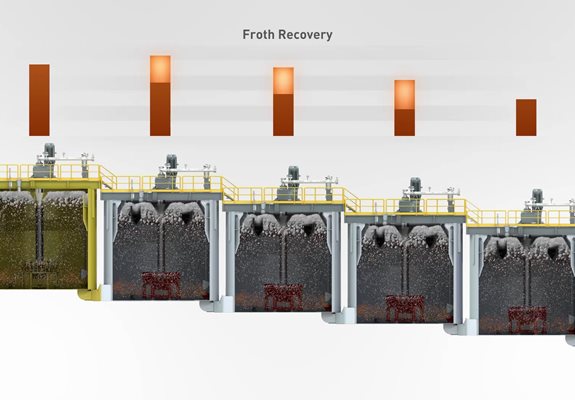

Both collection recovery and froth recovery need to operate efficiently to obtain maximum recovery.

Collection recovery involves combining slurry, air, and chemical reagents in a tank and agitating them to create bubbles that carry valuable materials to the surface.

The froth must be promptly collected to the launder lip to maximize froth recovery.

Optimal flotation recovery is achieved when these two processes work efficiently in harmony.

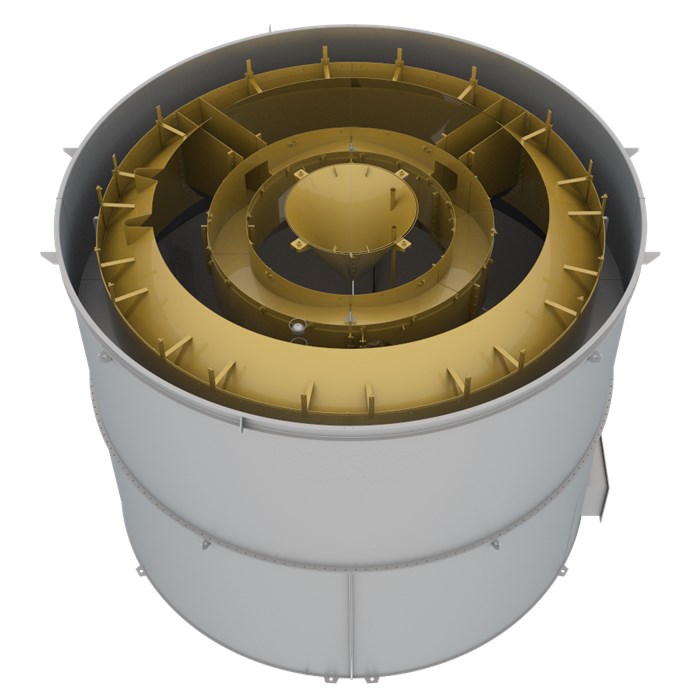

The Metso center launder upgrade is composed of three parts:

- Center launder

- Outer crowder

- Froth cone

Each tailor-made for your site to address your specific conditions.

The center launder radically reduces the froth transport distance to the launder lip.

A shorter transport distance enhances the likelihood of froth overflowing the launder lip. The longer the transport distance the more likely the bubble is to burst, resulting in the valuable material sinking back to the bottom of the tank, and being carried out with the tailings.

The new froth cone and outer crowder maximizes froth recovery and creates a thicker, more stable, and more productive froth. Both the cone and crowder push the froth towards the center launder.

This is especially important near the end of the circuit, after all the fast floating and well-liberated particles have been reported to the launders.

The Metso center launder adjusts the froth area produced by the equipment in each cell, resulting in higher froth recovery and higher concentrate mass pull, and higher recovery throughout the circuit. The cells recover more valuable material reducing loss through the tailings.

This is achievable through current equipment with no additional operating expenses in the form of water or reagents.

Improved recovery in the flotation circuit is possible through one positive, sustainable, and efficient upgrade.

Find out how our center launder upgrade resulted in a 0.70% higher Copper and 1.40% higher Molybdenum recovery at Constancia mine here.