The New Afton mine is a Cu-Au operation of New Gold Inc., located 10 km from Kamloops, B.C. in Canada. The flotation rougher circuit includes a line of six Metso Outotec TankCell®100. In 2019 the flotation performance was studied, concluding the need for higher froth recoveries specifically in the last cells of the rougher line. As a result of the study, Metso Outotec recommended a center launder upgrade of the last two cells in the row.

The center launder upgrade

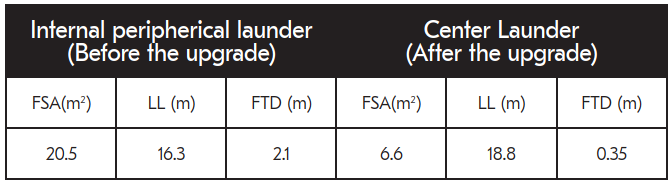

Previous similar upgrades have documented substantial metallurgical improvements as a result of the optimization of the Froth surface Area (FSA), Lip Length (LL) and Froth Transport Distance (FTD). The cells were staggered retrofitted with center launders: Cell 5 upgraded in September 2020 and Cell 6 in February 2021, as seen in table 1 details froth zone modifications.

Benefits

- Optimized froth zone

- Higher ability to overcome inherited process instabilities

- Deeper froth beds for better froth stability

- Higher Jg’s for maximized froth mobility

- Reduced airflow consumption

Table 1. Froth zone parameters comparison in New Afton. After the upgrade, FSA and max. FTD decreased 68% and 83% relative to the value before respectively.

After the installation, New Afton’s metallurgy team and Metso Outotec experts

undertook a holistic assessment to study and optimize the new operating settings of the upgraded cells.

Optimization

1. Remote data analysis and pre-assessment

Metso Outotec experts remotely analyzed historical data shared by New Afton’s team, this allowed the planning of the sampling campaign prior to the visit with the objective of studying the performance of cells 5 and 6.

2. Onsite sampling campaign

On July 6th and 7th of 2021 Metso Outotec experts visited New Afton to perform

a sampling campaign. The plant was stable during the campaign. Airflow was varied from the minimum to the maximum operational possible value, the froth bed remained constant.

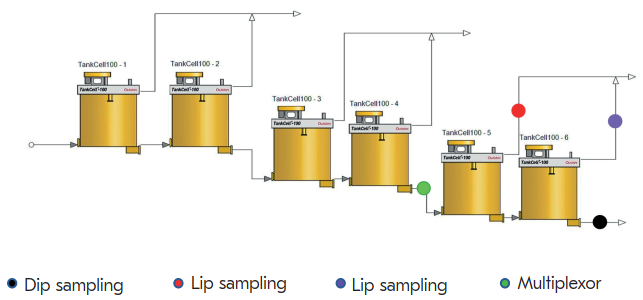

Figure 1. Sampling points in New Afton’s rougher circuit

Feed to cell 5 was cut with a dip sampler and final tailings from the existing Metso Outotec Multiplexor. Lip samples were obtained with a tailored lip sampler, this allowed for direct correlation of the froth zone characteristics by timing each sample round.

3. Data reconciliation and mass balancing

After New Afton shared the assay’s results, Metso Outotec proceeded to analyze and mass balance using HSC® Chemistry. Once the balance was ready, the team of experts analyzed the data to provide recommendations based on Metso Outotec flotation cell design criteria.

4. Reporting and advisory

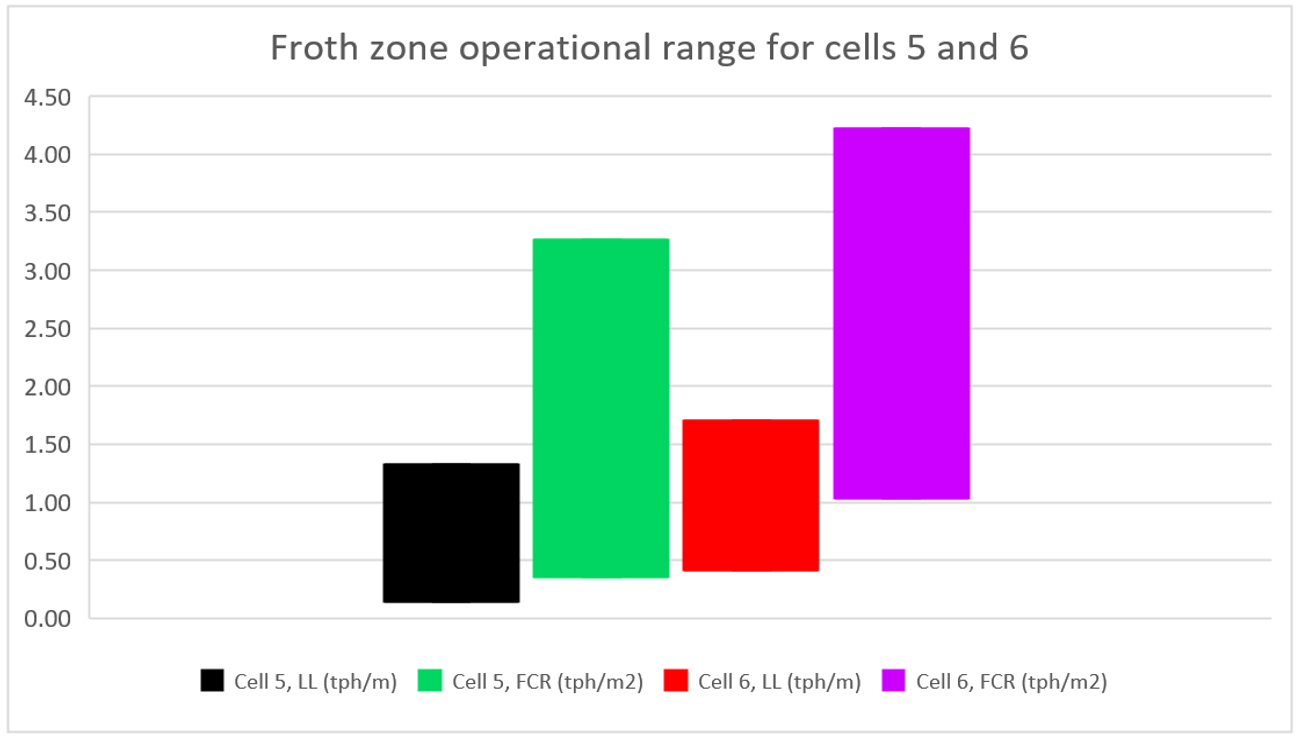

Metso Outotec and New Afton discussed the results of the report. It was clear that the increase in Superficial Gas velocity (Jg) due to the upgrade impacted in higher mass pulls, resulting in a wider cell’s operational range to overcome the inherited instability of the process in terms of Lip Loading (LL) and Froth Carrying Rate (FCR).

Figure 2. Operational range after the center launder upgrade.

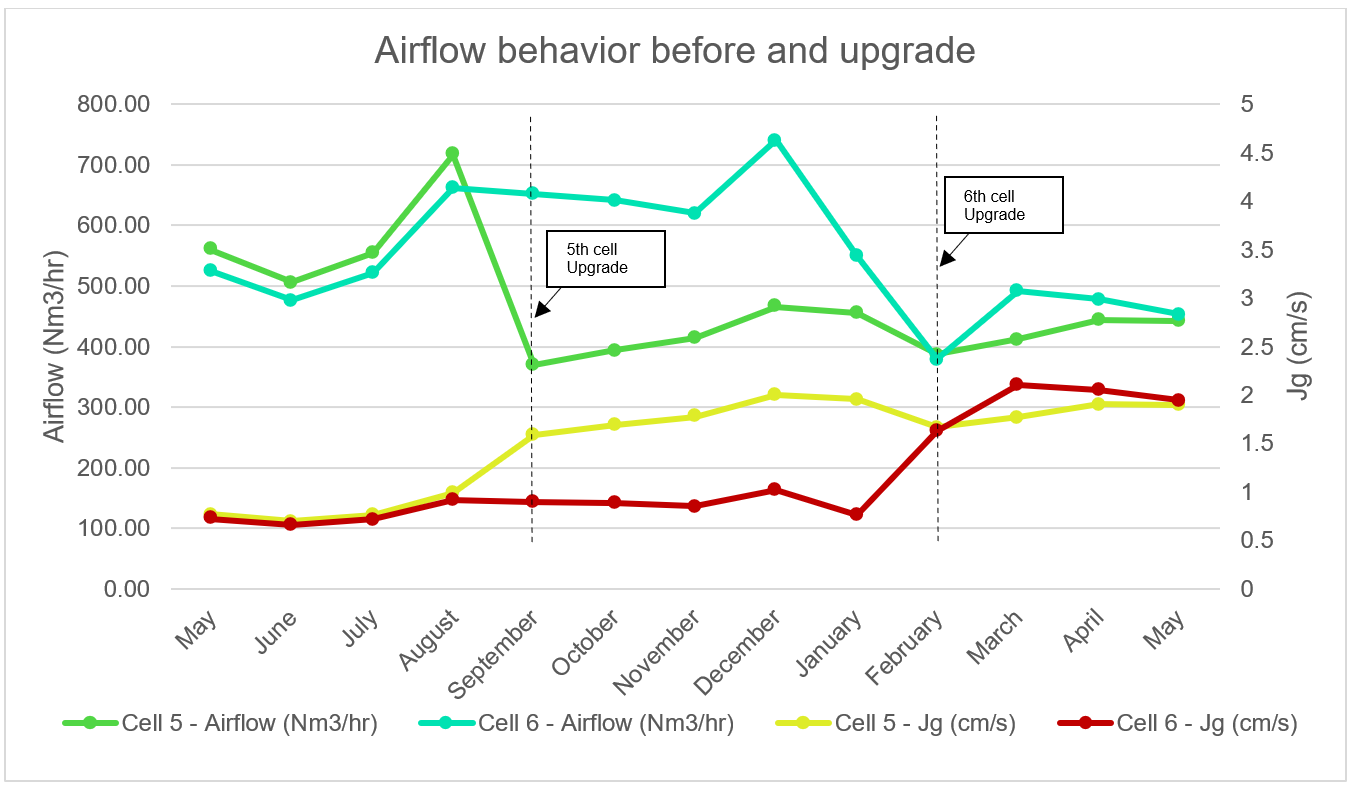

Figure 3. Airflow rate and Jg throughout the upgrade period

Results

- The Center Launder Upgrade resulted in a reduction of 68% for froth surface area and 83% for froth transport distance

- The upgrade enables a wide operational range: Lip Loadings up to 1.7 tph/m for cells and Froth Carrying Rates up to 4.2 tph/m2

- Optimized operational parameters resulted in improved recovery without excessive water and gangue recovery

- Increased crowding resulted in higher Jg’s, up 2.7 cm/s without any disturbance in the froth zone

- Higher than industry’s average air efficiency, up to 46.3 kgConc/m3air

- Reduced airflow after the upgrade on average of 22%