State-of-the-art technology for sustainable and cost-efficient production of high-quality copper

Complete process and equipment performance guarantees

Lower total cost of ownership through high quality proprietary equipment

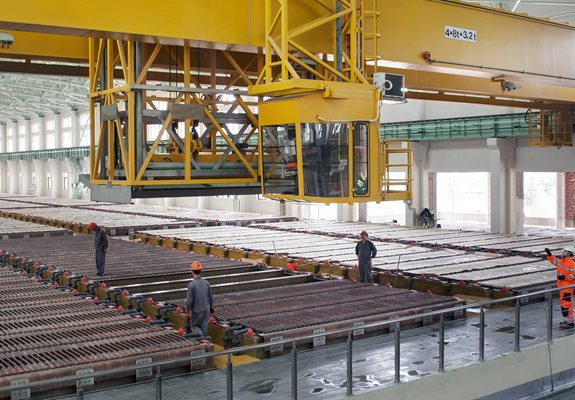

The electrorefining process

Introducing Metso electrorefining technology

Metso is the leading provider of copper refining technology, with the industry’s widest range of solutions and a proven track record. Our electrorefining solution covers the entire refining process chain from anode to cathode. It integrates our process know-how and proven material handling technologies with advanced process control, resulting in a holistic system where all interfaces are optimized for high performance and quality.

Designed to minimize operational challenges throughout your plant’s life, our electrorefining technology is suitable for both new and existing operations.

Core benefits:

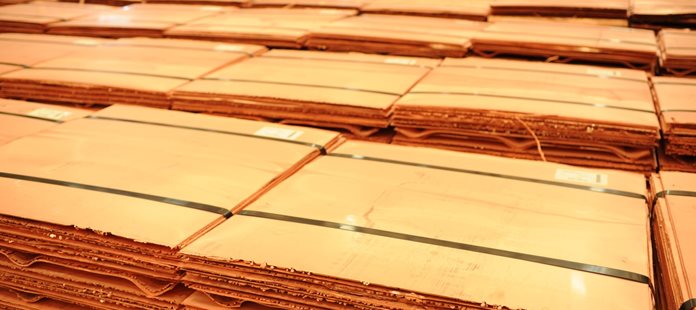

- Production of high purity cathode

- Improved occupational and environmental health and safety

- Lower total cost of ownership through high quality design and manufacturing

- Minimized cathode replacement costs

- High automation

- Low emissions into air

- All waste recycled back to smelter

- Global service network support

Electrorefining comprehensive scope of supply

Metso electrorefining technology covers all process steps in a copper refinery. We provide the tankhouse with an unbeatable combination of electrode handling system and innovative process technology including permanent cathodes. Our professional engineering and project management capabilities ensure smooth implementation, while our comprehensive customer service minimizes operating risks throughout the lifecycle of the plant.

|

CORE |

ENABLERS |

SERVICES |

|

Metso® permanent cathode Metso’s cell and anode designs |

CellSense™ cell voltage monitoring Proscon process control system Online cathode inspection Main busbar systems |

Spares Startup Audits Flowsheet development and studies Kinetic batch testing of leaching Modernizations Technical services |