Achieve excellent environmental performance with low investment and operating costs.

- Works with a variety of primary, secondary, and waste feed materials

- Operates under various conditions: from highly oxidizing to highly reducing and across a wide temperature range

- Offers a high production capacity with a small process footprint

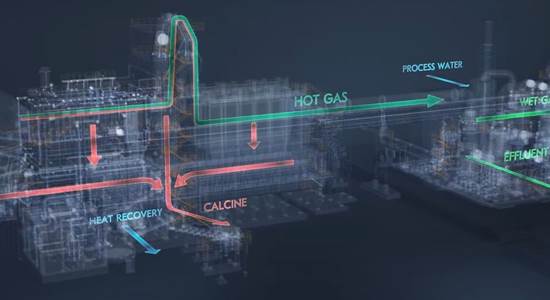

- Captures process off-gas and dust efficiently

- Has low investment and operating costs

- Provides an environmentally sound process solution