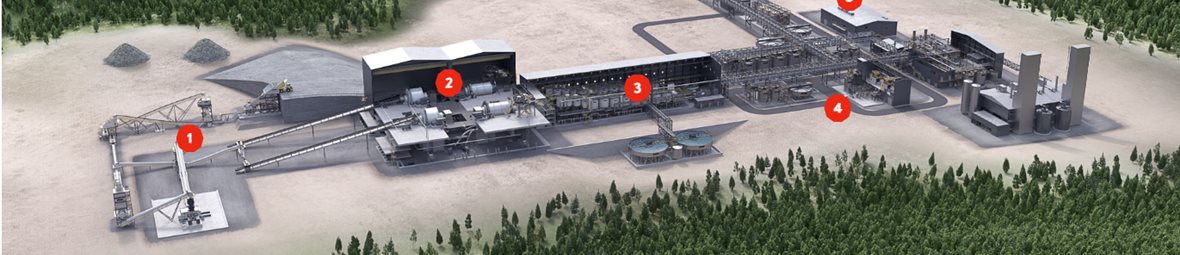

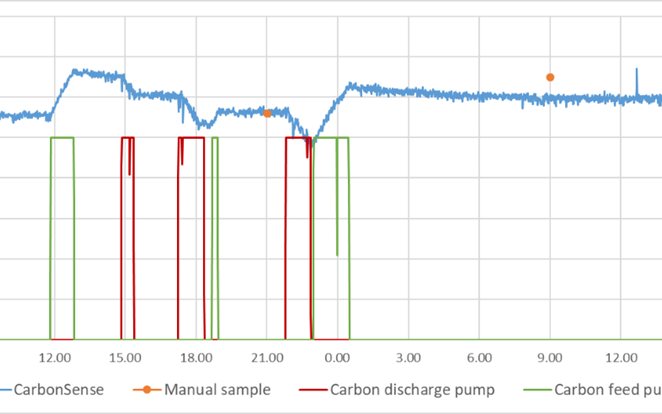

Minimizing gold solution losses in CIP and CIL circuits requires optimized carbon management. However, carbon management in the circuit is often suboptimal due to infrequent measurement of carbon concentration and manual control of carbon movement between the tanks. Metso CarbonSense addresses this issue by introducing a reliable and repeatable method for the online measurement of carbon concentration.

Advanced Carbon Management

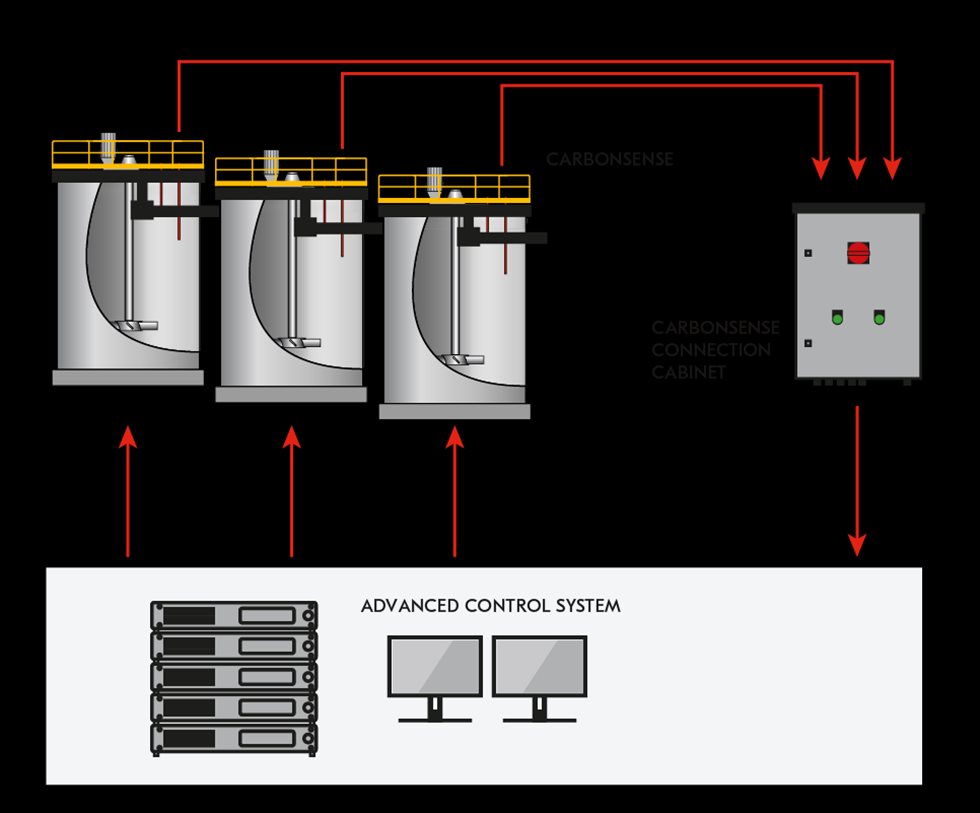

The continuous and reliable carbon concentration measurements provided by CarbonSense make it possible to accurately control the transfer of carbon between reactors and thus minimize gold losses. The Metso Carbon Management application has been specifically designed to take full advantage of the CarbonSense measurements for a tank. Further, the solution can be expanded to a CIL Optimizer which optimizes the carbon transfers between the tanks and maximizes yield out of the circuit.

CarbonSense Connection Cabinet

The CarbonSense Connection Cabinet provides a central connection point for up to 8 measurement assemblies, featuring both fiber-optic and copper media connections to the plant network. The system supports virtually any network topology, such as the star or ring configurations. The system is designed for easy maintenance access, having all the power supply units and fuses for the

measurement assemblies in one convenient place.

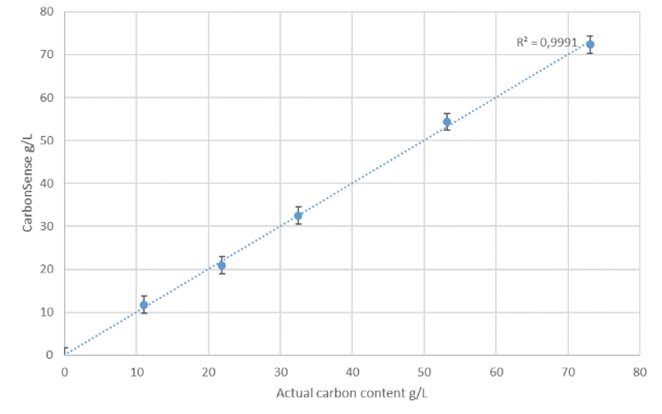

On-Site Calibration

The calibration of the CarbonSense system is carried out accurately and quickly. The use of authentic slurry and carbon in the calibration unit ensures the best possible calibration results and consequently a reliable measurement. The system doesn’t require recalibration if the process conditions remain similar.

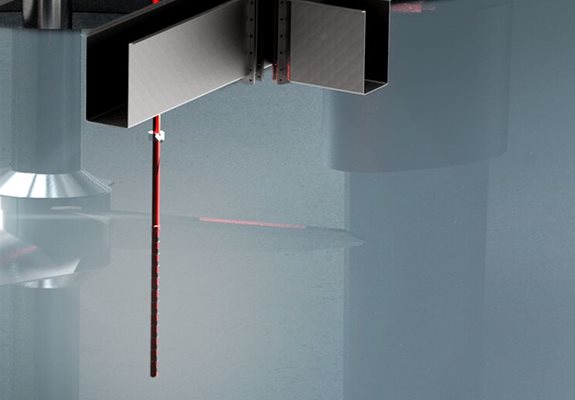

In-Situ Carbon Concentration Analysis

This in-situ nature of the measurement also eliminates the need for potentially unreliable sampling systems,

thus making the system robust.

The main advantages of CarbonSense are:

• Simple and robust measurement principle

• Representative and reliable analysis

• Continuous measurement

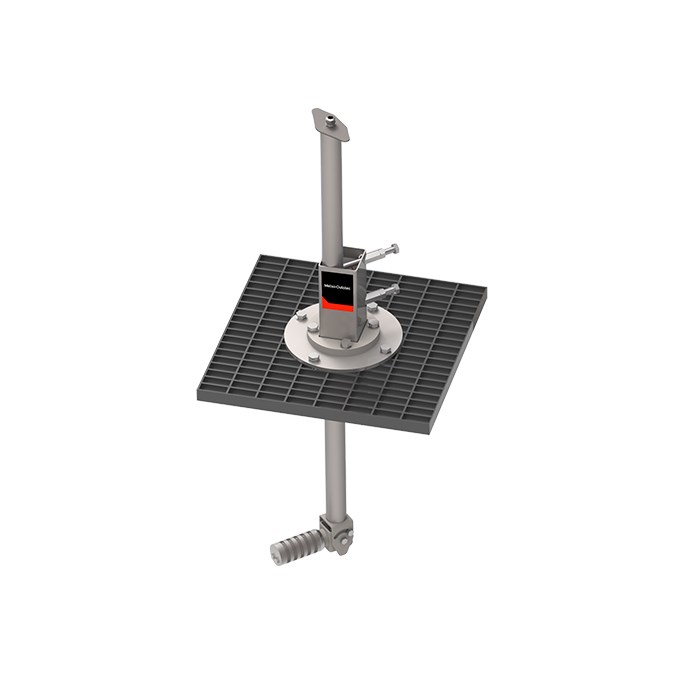

CarbonSense Measurement Assembly

The measurement assembly contains an electronics box and two probes. The measuring probe and reference probe has 5 stainless steel electrodes at regular intervals, separated by insulating layers. The carbon content is measured by running a small electric current through the probes, measuring the voltage differentials between electrodes and comparing the measuring probe’s differentials to the reference probe.