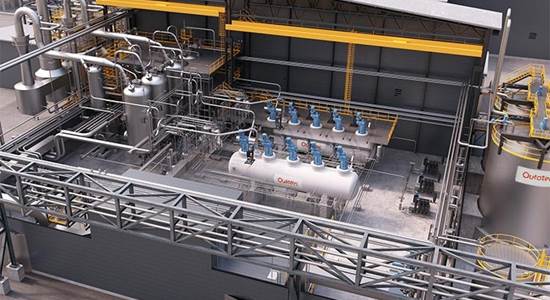

The Metso OKTOP plant unit is a full solution for performing metallurgical tasks over multiple reactors. The plant unit may also include other equipment, such as gas cleaning scrubbers. Different reactors are typically joined together with a launder. The launder offers flexibility enabling one or more reactors to be isolated from the plant unit, while still allowing others to operate as required.

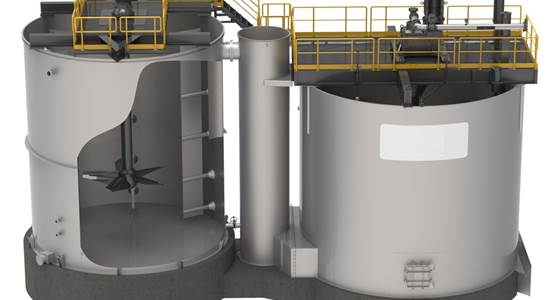

The Metso OKTOP reactor product group is proprietary equipment that includes its own agitator series designed to suit specific mixing purposes and process requirements. The plant unit's reactor may also be equipped with cooling or heating baffles. Metso OKTOP heating baffles provide improved heat transfer and reduced reaction times. The heating medium used in the heating baffle is usually high-pressure steam. Metso has experience in delivering pressure equipment and can fulfill all the required delivery procedures to ensure swift approval for the operation with local authorities for both ASME and PED standards.

Metso OKTOP cooling baffles remove excess heat from the solution using a leaching reaction. The second generation cooling baffles used in this application are designed for improved heat transfer with improved maintenance and operational access. All connections to the cooling baffle are through the tank roof and the removal of the cooling baffles can be performed through the roof.

The Metso OKTOP launder connects reactors to form a plant unit, facilitating operation and maintenance and removing the need to pump slurry from one reactor to the next. The launder is comprised of standard units including a feed box, the required number of I/O sections, and an outlet box. The gravity flow concept is based on a proprietary design that ensures a smooth solution and solid particle transfer from one reactor tank to the next.

In addition to the reactors and launder, the Metso OKTOP reactor plant unit usually includes all the support structures, footbridges, and maintenance platforms necessary for efficient and safe operation. Reactors may include accessories such as a corrugated bottom. Application-specific products such as gas cleaning scrubbers for processes with dangerous exhaust gases, or carbon transfer pumps for CIL circuits, can also be included if required.