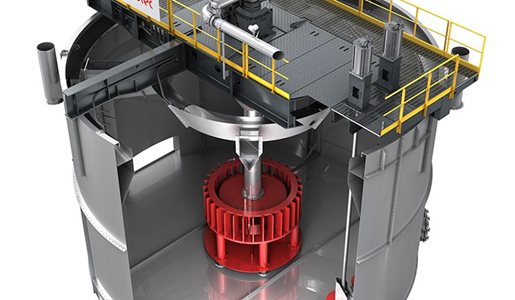

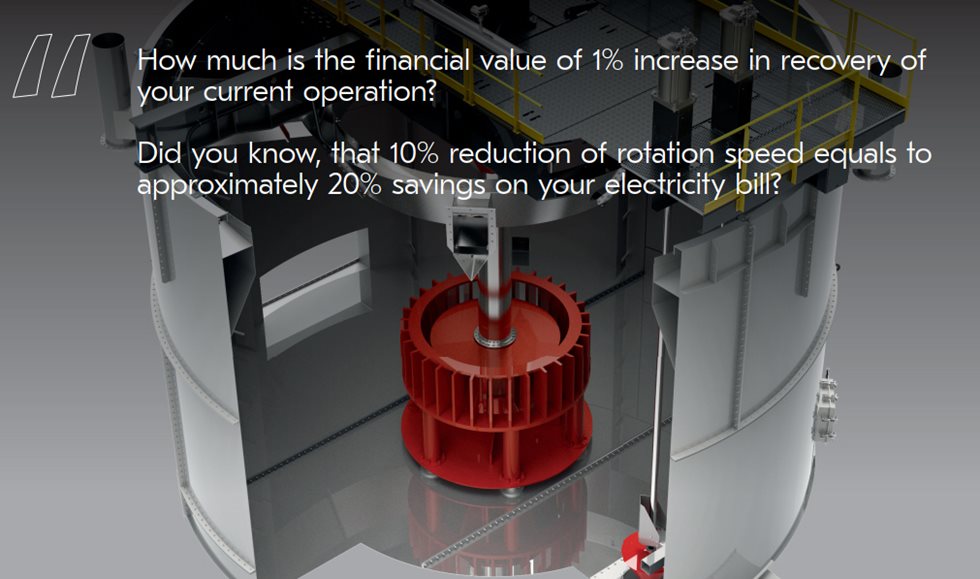

Upgrades that improve performance to help you reach your sustainability targets

Quicker, simpler, and more cost-efficient maintenance

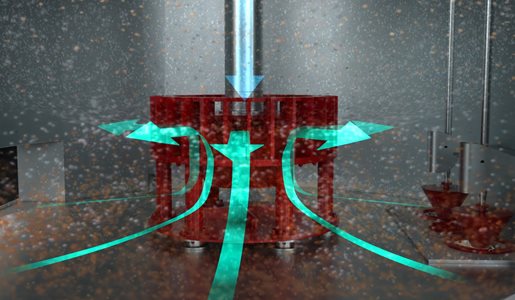

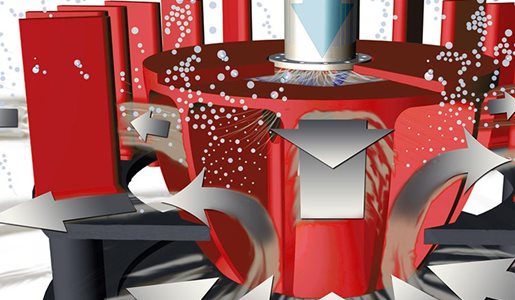

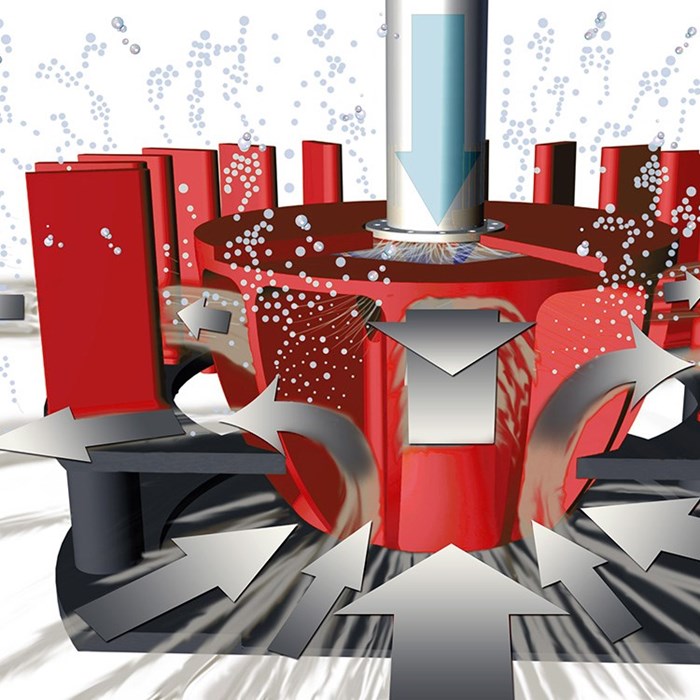

Improving flotation hydrodynamics and pumping performance at high air dispersion rates enhances particle recovery

- Increased recovery

- Lower energy consumption

- Improved wear life

- Quicker, simpler, cost-effective maintenance

The mixing mechanism performance has a direct impact on the three key areas of flotation

FREQUENTLY ASKED QUESTIONS

The Metso FloatForce mechanism is available as a retrofit upgrade for any brand of flotation cell. Our service professionals deliver the complete package including the hardware, mechanical engineering, installation supervision, and metallurgical expertise.

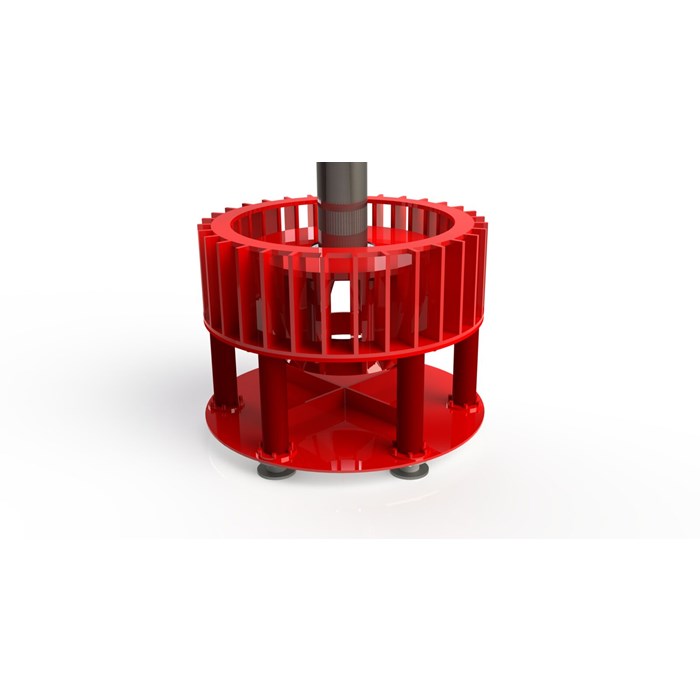

- Rotor

- Stator and stator stand

- Wear plate and parts for tank bottom

- Installation support from Metso experts