Benefits

Long wear life and a perfect fit

Tailor-made design for optimum performance and mill utilization

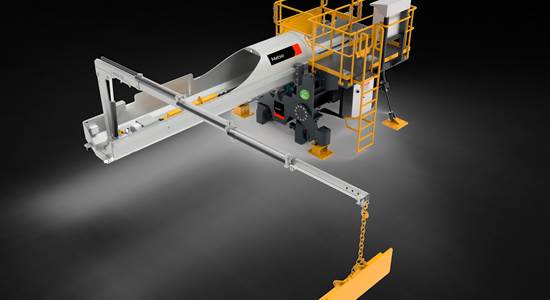

Fast and safe installation due to optimized mill liner installation systems and methods

High-performing parts improve efficiency, and long-lasting liners mean fewer parts are needed

Metso metallic mill linings are always designed with one thing in mind: to maximize performance and minimize replacement time.

The solution offers total freedom of design and the possibility to optimize your lining based on operating data and liner handler capacity. Using linings of a modern design and maximized size minimizes the number of liners needed – and thereby your downtime.

We have made the world’s largest liners, weighing 8 tons.

Metso metallic mill linings are produced at our own foundries. Our chromium molybdenum steel and high-chromium white irons are specially developed for mill lining applications and are carefully selected based on the operating conditions of each mill.

Our foundries apply strict quality assurance programs at every phase of research, development, design and production. This ensures high and uniform quality for the entire supply. Precise dimensions and close tolerances guarantee that your mill lining has a perfect fit.

Combine for better results

Metso offers mill linings with materials and designs optimized for each specific application. We work closely with our customers and carefully follow their process to make sure the lining we supply is always optimized for current operating conditions. We can design and supply mill linings for all types of mills - for Metso mills as well as for competitor mills - and for all parts in the mill. Our wide product range, innovations, knowledge and experience make us unique. Our approach to lining design is focused on grinding performance, mill uptime and safety/sustainability.