Safe and efficient relining of smaller mills

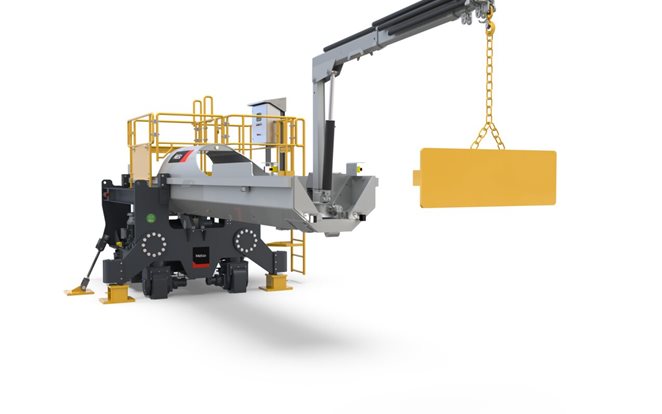

Mechanical assistance is a critical requirement for safe relining and is often challenging in smaller SAG and ball mills. The Metso Tube MRM provides fixed three-axis hydraulic crane support for relining tasks in mills that are unsuitable for traditional reline machines. This ensures stable lifting and minimizes time lost during mill inching.

Lower capital cost and simplified maintenance

The main tube structure maximizes both the structural support through small mill openings and the open space available for liner delivery. This streamlines the relining process by allowing the machine to use a high-capacity crane and large liner designs. The simple tube design decreases both maintenance requirements and machine cost due to the reduced number of moving components.

Industry-leading safety features

A range of safety systems is provided as a standard to provide the highest possible level of protection for personnel. Rated capacity limiting and installation monitoring mitigate the risk of instability and overload during operation, while remote-control operation and hydraulic spool monitoring prevent unexpected machine movement. All safety systems can rapidly cut hydraulic power if a dangerous situation is detected.

Our services portfolio includes:

- Full mill reline equipment package including Metso Mill Equipment Transporter (MET), Metso Mill Reline Machine (MRM), Metso Tube Mill Reline Machine (Tube MRM), bolt hammers, and support tooling

- Equipment inspection, maintenance, and training services

- Remote troubleshooting support

- OEM spare parts and spare parts advisory services, and easy online parts identification and ordering