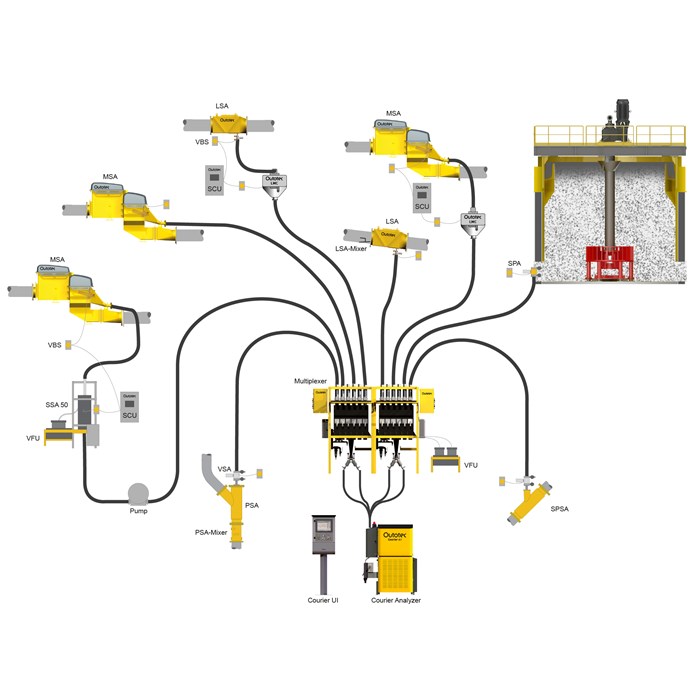

Designed for a wide range of applications, our sampling solutions help our customers improve sampling reliability and representation, minimize maintenance costs, and extend the operational life span of the sampling system.

Metso specialists help specify a solution that meets customers’ needs precisely and supports a range of life cycle services.

Ensure optimal performance with our sampling modernization assessment

Our sampling modernization assessment provides a comprehensive analysis of the condition and performance of the existing systems and identifies areas for improvement. The assessment ensures sampling validity for balancing and accounting and guarantees optimal sample availability and representativeness with minimal maintenance costs. It also verifies the correct sampling points for process-control purposes.

How we analyze the sampling process

Our in-depth sampling modernization assessment will cover the following issues:

- Purpose of the sample required?

- Source of the slurry being sampled?

- Destination of the process stream and sampled material?

- Future process changes expected, such as a significant increase or decrease in process flows?

- Whether the sampled material contains significant amounts of waste, rocks, grinding balls, or acid?

- Are samplers correctly located and installed? Both of these factors can have a significant effect on sample representativeness.

What you can expect

- Reliability and accurate representation

- Increased safety and convenience with next-generation sampling control

- Improved sample availability and reduced return volumes with on-demand sampling