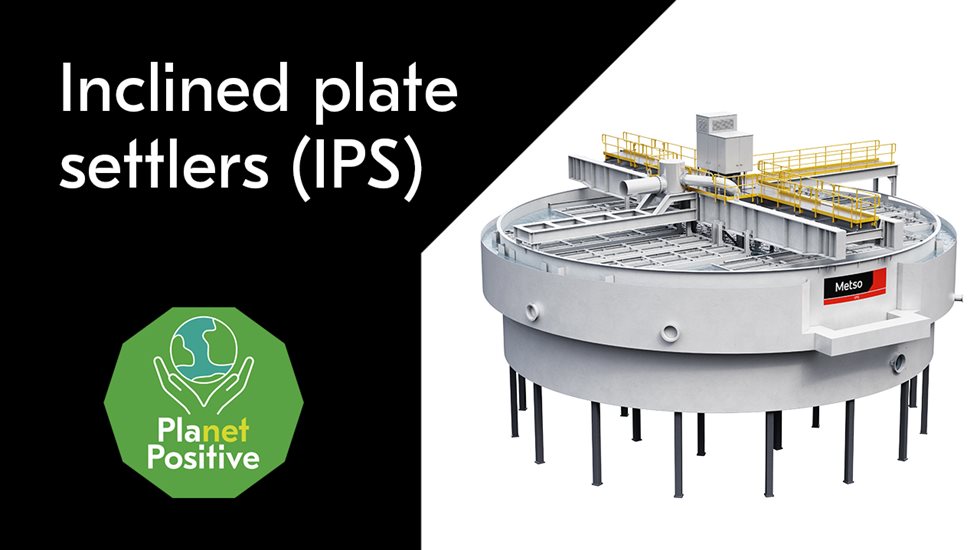

Metso inclined plate settlers (IPS) uses a unique lamella principle, which has proven to be more efficient and sustainable than conventional clarifying and thickening methods in water treatment and dewatering. The lamella principle the Metso IPS use involves several parallel inclined plates to maximize the available floor area. The size and costs of the gravity settler (IPS) can be minimized by matching the thickening and clarifying requirements thoroughly.

Metso's inclined plate settlers (IPS) is a proven compact sedimentation and dewatering solution. Metso’s IPS offers good clarity of the overflow liquid and maximum density of the underflow solids discharge with minimum space requirements. Easy to install, relocate and adapt to process changes with a wide product offering for a range of applications, the Metso IPS offers maximum return on investment to customers.

Reduced plant footprint

Saving space in a plant is key to maximize space, reduce and simplify the needed planning, but most importantly will be a cost saver. In comparison to conventional thickening and clarifying equipment, the Metso inclined plate settlers (IPS) provide up to a 85% smaller plant footprint.

The design of the parallel inclined plates allows the equipment to be constructed vertically instead of increasing the area needed. Even with Metso's newer IPS model designs there is a significant reduction in floor space without sacrificing results.

Increased uptime

Metso IPS has a robust design with the unique lamella principle allows gravity to aid in increasing uptime. As the slurry is transferred into the IPS the vertical design allows for maximum throughput with minimal disturbances in the flow.

The robust design comes from the heavy duty construction of the tank, sludge hopper and inclined plate pack. The wide density of inclined plates are specifically designed for no short circuiting causing the need for maintenance. The feed ports are also designed for creating an optimum ratio between the clarification and thickening area.

Metso inclined plate settlers (IPS) are also known to have reduced installation time so the equipment can be put into operation faster.

Lower environmental impact

Metso inclined plate settlers (IPS) focuses on environmental impact and reducing that as much as possible. Avoiding water wastage is one of the key goals and being able to reduce tailings mine waste. With up to 10% less chemicals used in the Metso inclined plate settlers (IPS) will make water recirculation and recovery easier.

A smaller foundation and floor space requirement converts into less construction to the environment needed when building the plant. The IPS is easily insultated against heat loss or toxic fume emissions reducing pollution levels.

The increasing of compact sedimitation and dewatering allows for safer disposal and less tailings mine waste downstream.

Lower costs

Metso inclined plate settlers (IPS) proves to reduce costs compared to conventional technology. Decreased CAPEX derives from smaller floor space and foundation requirements, and easier planning and construction due to the square design. The IPS is also delivered as a one-piece unit or fabricated sections compared to conventional on-site labor costs for dramatic assembly.

OPEX reduces by up to 10% compared to conventional technology. The Metso inclined plate settlers (IPS) are flexible throughout operation with adaptability and easy relocation if needed. Metso's IPS performs a cost-efficient operation and provides up to 70% saving energy consumption compared to conventional thickeners and clarifiers becoming a large OPEX cost saver.