Increase energy efficiency and life-of-mine

Almost half of the energy consumed in the mining industry results from crushing and grinding operations. Together with declining ore grades and water shortages, this means that innovative, sustainable process solutions are urgently needed to improve efficiency and meet ever-stricter environmental regulations in both greenfield and brownfield operations.

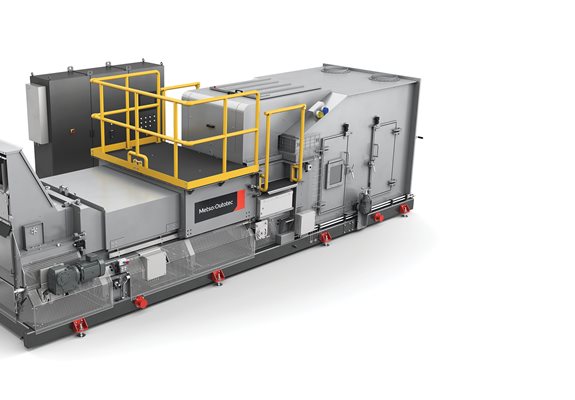

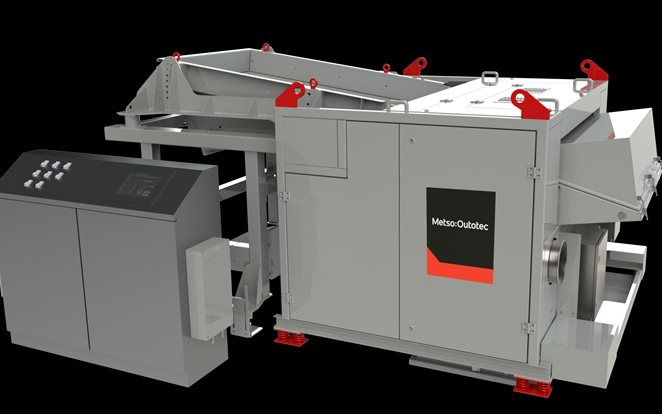

Thanks to rapid development in established sensor technologies, sensor-based ore sorting is capable of transforming the outlook of the mining industry. TOMRA sorting technology combined with Metso's comprehensive process know-how and plant-engineering expertise offers you the most productive and sustainable process solutions for base and precious metals segments.

Reliable and cost-effective solutions

Our user-friendly, reliable, and low-maintenance technology will help you meet the demanding uptime and durability requirements of your mining projects. Additionally, wear is limited to a small number of parts, meaning that your personnel can perform basic maintenance activities on-site.

Our sorting equipment is easy to integrate into your process, including a secure data connection for software updates and remote access for diagnostics. Sensor-based sorters are cost-effective, as they require no chemicals and minimal water – only electricity and clean pressurized air. Our solutions are designed for high performance in a wide range of operating conditions.

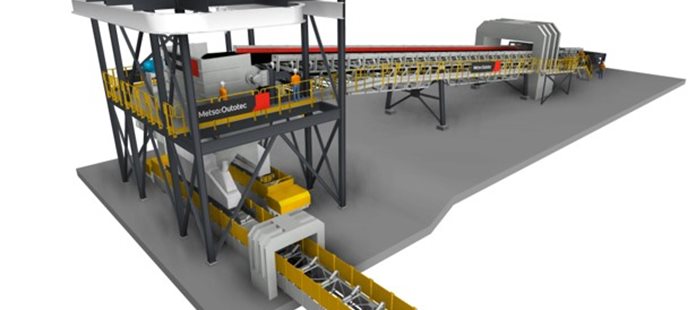

Turnkey state-of-the-art solutions

Metso has the expertise and capabilities to design, supply, and build state-of-the-art sorting plants to meet the needs of most mining projects, with a fast and reliable ramp-up. Our global presence means that we can provide support to you worldwide during your plant's entire lifecycle.

For green and brownfield mining projects, we offer:

- Ore sorting test works

- Conceptual studies for sorting plants

- Basic and detail engineering for sorting plants

- Project scoping, pre-feasibility, and feasibility studies

- Downstream process optimization

- Financial analysis modeling and valuation

- Capital and operating cost estimation

- Process equipment and consultation

- Automation and instrumentation

- Plant logistics capability assessments

- Plant engineering and infrastructure design

- Ore reserve evaluation and mine planning

- Plant production capability assessment

- Construction, installation, and commissioning services

- Operation and maintenance services

- Estimation of manpower and management requirements

- Implementation scheduling

- Production and development scheduling