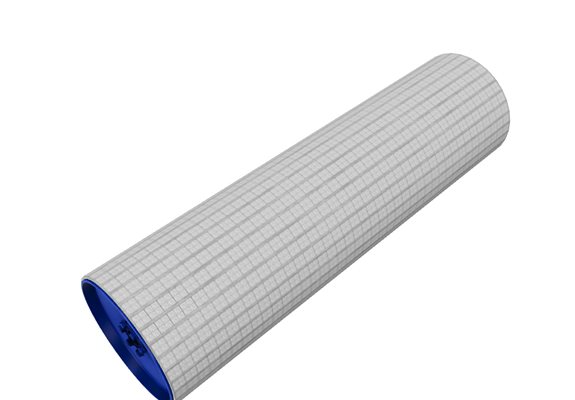

About Trellex® Cerlag direct bonding ceramic pulley lagging

Application

Aluminum oxide tiles in the Trellex Cerlag DB (Direct Bonding) ceramic pulley lagging are bonded directly to the pulley shell using a high strength epoxy adhesive. For drive pulley applications tiles with dimples are used and for non-drive pulleys plain/smooth tiles are used. The adhesive has good properties at both low and elevated temperatures and can operate in pulley lagging applications from -20 C to +70 C.

Design

The Trellex Cerlag DB pulley lagging is designed for use on drive and non-drive conveyor pulleys. This lagging provides a maintenance free wear resistant surface that will provide increased traction for drive pulleys and a smooth low friction surface for bend and tail pulleys.

The ceramic tiles are based on a high performance aluminum oxide that is dry injection pressed and sintered under tightly controlled conditions. This produces a small particle size ceramic with outstanding physical properties, abrasion and flex crack resistance. The tiles are supplied in pads with clear backing tape to ensure accurate positioning.

Ceramic lagging with dimple tiles issued on drive pulleys to increase grip and ceramic lagging with smooth tiles is used on non-drive pulleys to increase wear resistance/service life.