Calculate your need

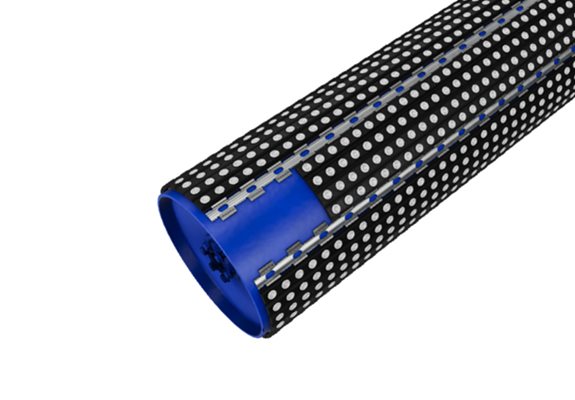

There are two ways of applying slide laggings:

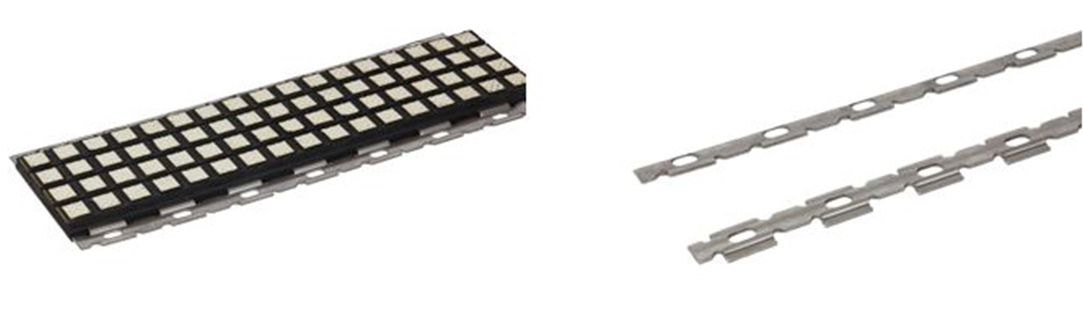

The butt seam method which is the most economic option. Pads are cut to fit the pulley face width and the remaining ends of each cut pad are used butted together. Pieces shorter than 100 mm should be discarded.

The full width method when no butt seams are desired. Each pad row is provided with full face width pads that have no butt seams. Example pulley diameter 600 mm & face width 1000 mm.

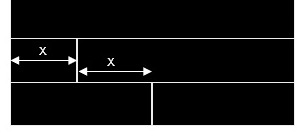

Butt seam method:

1.

Number of rows = Pulley diameter x 3,14

160

Number of rows = 600 x 3,14 = 11,775

160

Round down to closest whole number -> 11.

2. Multiply the number of rows of pads by the pulley face width, divide with 1687 (full length pad in mm)

11 x 1000 = 6,5

1687

Round up to closest whole number -> 7 full length pads required.

Butt seam method X min 100 mm

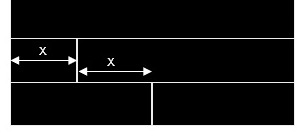

Full width method:

1. Same as 1. above.

2. Calculate how many full width sections you can get from a standard size pad.

1687 = 1,7

1000

Round down to closest whole number -> 1.

3. Divide number of rows with how many full widths you can get out of one pad.

11 = 11 -> 11 full length pads required.

1

Retainers:

Double retainer = (Face width + 500mm*) x number of rows = 5,7 -> 6 pcs

Length of retainer

*Retainer length/Row = Face width + 25mm on each side.

Single retainer = (Face width + 50mm*) x 2** = 1,03 -> 2 pcs

Length of retainer

**Always two.