Why partner with Metso?

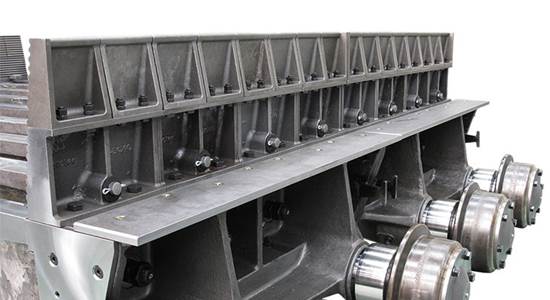

Increased uptime

Increased equipment reliability prevents unplanned shutdowns due to failure of stressed components.

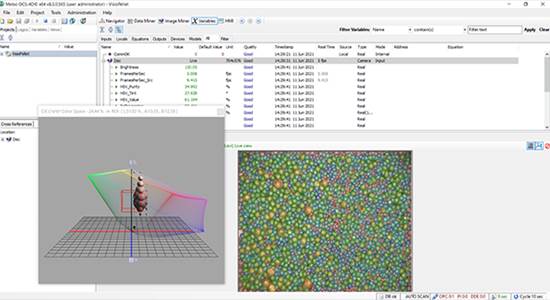

Operational flexibility

Maintain productivity despite raw material changes.

Operating efficiency

Maintain production capacity and process efficiency.

- Maintains original productivity by using up to 50% of < 150 µm

- Keeps operational flexibility with changing raw material base

- Enables process guarantees

- Minimizes shut-down period to reduce production loss