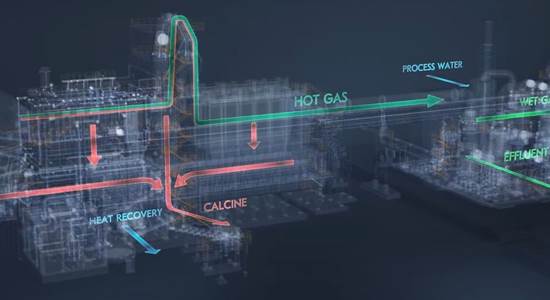

In the Metso's Outotec PS Converting Process, the molten matte from the smelting furnace is converted into blister copper. Converting is carried out in two stages. The first stage is the slag blow, where iron contained in the matte is slagged and removed before the copper blow phase. Here, the Metso Batch Charging System ensures an accurate and well controlled addition of silica or revert flux into the process resulting in an optimal slag composition. In the copper blow phase, most of the remaining sulfur is removed, leaving only small traces to be removed during the fire refining process. After converting, the blister is sent to fire refining and the slag from the converter is usually sent to slag treatment for copper recovery.

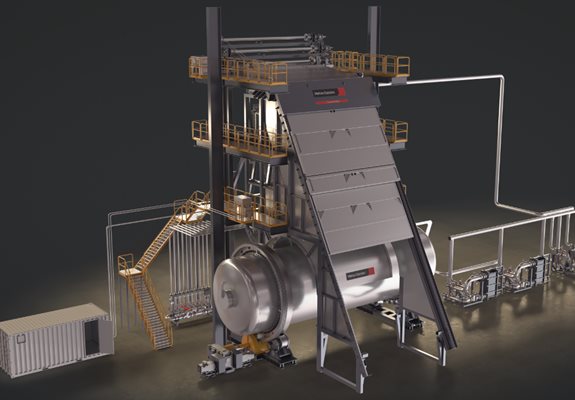

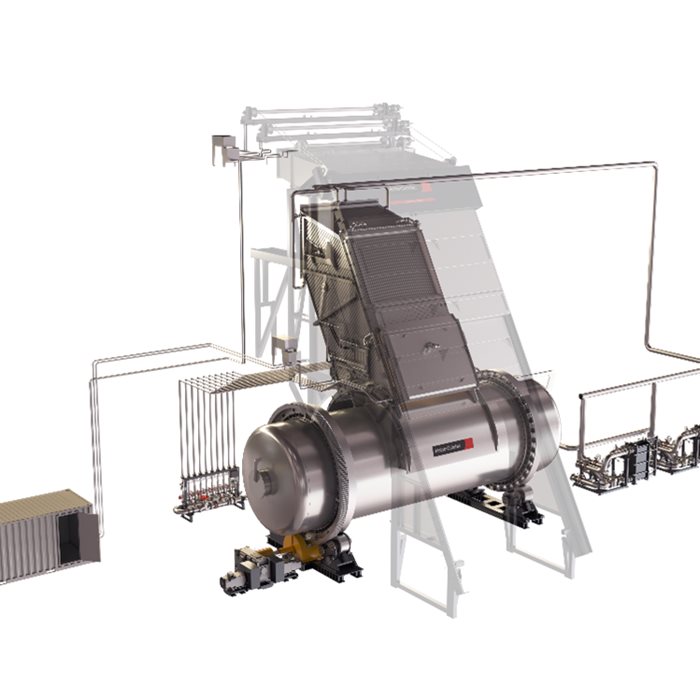

During the process, blast air is blown through the tuyeres, into the molten bath. The purpose of the Metso Punching Machine is to keep the tuyeres for blast air open thus allowing a stable blast air flow into the converter. The Metso Punching Machine is an automated machine controlled and overviewed from a control room to ensure a safe working environment for the operator.

The off-gas and fugitive emissions are collected in the Converter Hood System, that captures over 99% of the SO2 produced over a converter cycle and sent to cleaning and to acid production. The Converter Hood System design ensures minimized maintenance and long lifetime of the equipment.