Benefits

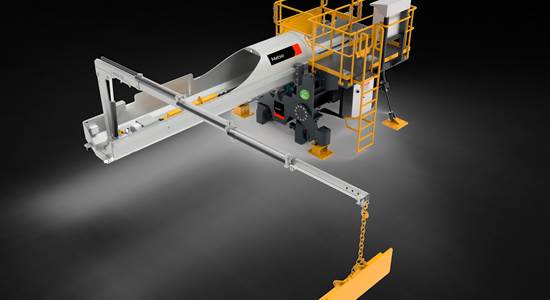

Safe and easy handling of light-weight components

Easy installation and replacement

Design based on experience, grinding performance and improved mill uptime

High-performing parts improve efficiency, and long-lasting liners mean fewer parts are needed

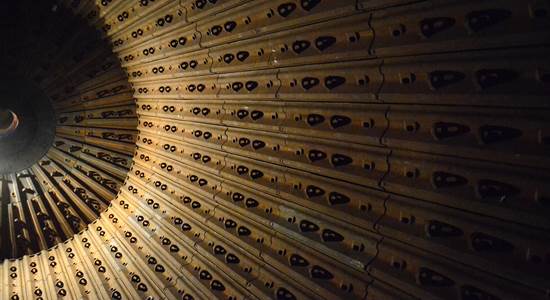

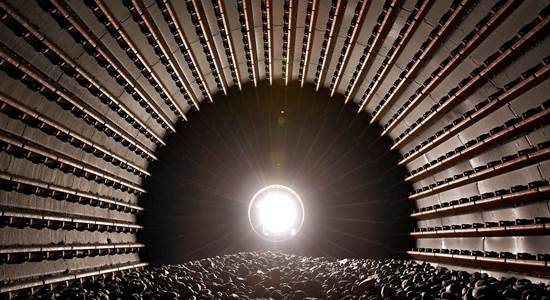

The Mill lining protects the equipment and has a large impact on mill performance. Grinding is a tough process, especially when grinding abrasive ores, and the mill liners plays a crutial role. Skega Life rubber will give you up to 25 % longer wear life, with extra value of increased sustainability, lower maintenance, improved safety, increased production though optimized throughput and increased uptime. Skega Life is part of Metso’s Planet Positive offering.

The new Skega Life compound is developed in Metso’s own lab and validated by field studies.

Since 1959, Metso has been in the forefront of developing wear and impact resistant rubber compounds to address specific operating conditions in all types of mills. Each compound is based on our experience in thousands of real-world applications.

By using our rubber mill liners, your working environment can be significantly improved. The rubber components are lightweight which makes them safe and easy to handle. Moreover, mill noise levels are reduced, as rubber acts as a vibration damper and noise filter.

Metso offers mill linings with materials and designs optimized for each specific application. We work closely with our customers and carefully follow their process to make sure the lining we supply is always optimized for current operating conditions. We can design and supply mill linings for all types of mills - for Metso mills as well as for competitor mills - and for all parts of the mill. Our wide product range, innovations, knowledge and experience make us unique. Our approach to lining design is focused on grinding performance, mill uptime and safety/sustainability.

Services for grinding

Discover our wide range of mill lining materials. Our ability to combine different materials in the same mill, using each material where it performs the best, enables us to optimize your grinding process, and make it more sustainable.