Benefits

Longer-lasting lining solutions equal fewer hours of maintenance, more uptime, and increased sustainability.

Clever fastening systems and remote monitoring allow quick and easy in-time maintenance.

Our in-house design and engineering team tailors the lining solution to fit your precise needs.

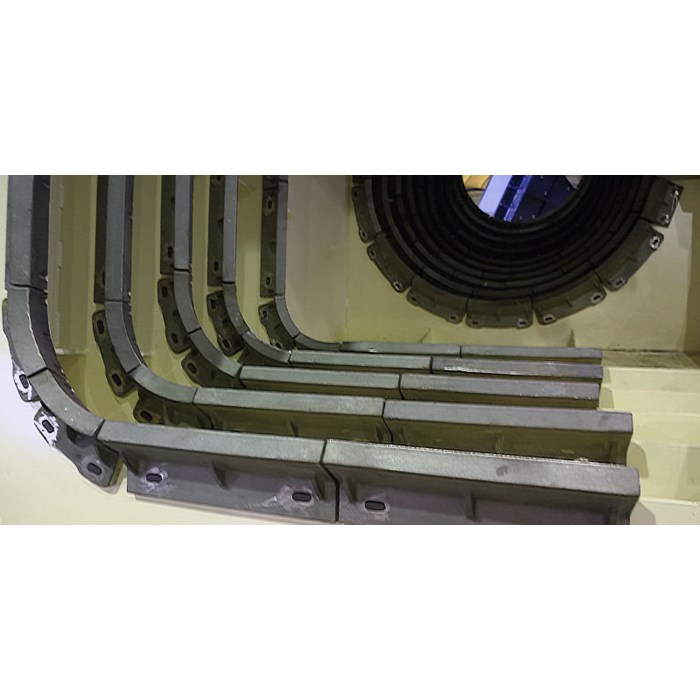

Utilizing a rock-on-rock design, the custom-built Wearback™ chutes take advantage of the build-up of material to significantly prolong wear life and this way lower the environmental impact compared to a conventional chute lining. Concentrating the ore stream and delivering the transported material with a softer loading at velocities and direction that closely matches the conveyor’s speed and direction minimizes the impact and wear on the conveyor belt.

Specialized range of ledge liners used on Wearback™ chutes to protect the parent metal. Consists of few parts and easy-to-handle small liners. The low weight lining provides excellent abrasion and impact resistance.

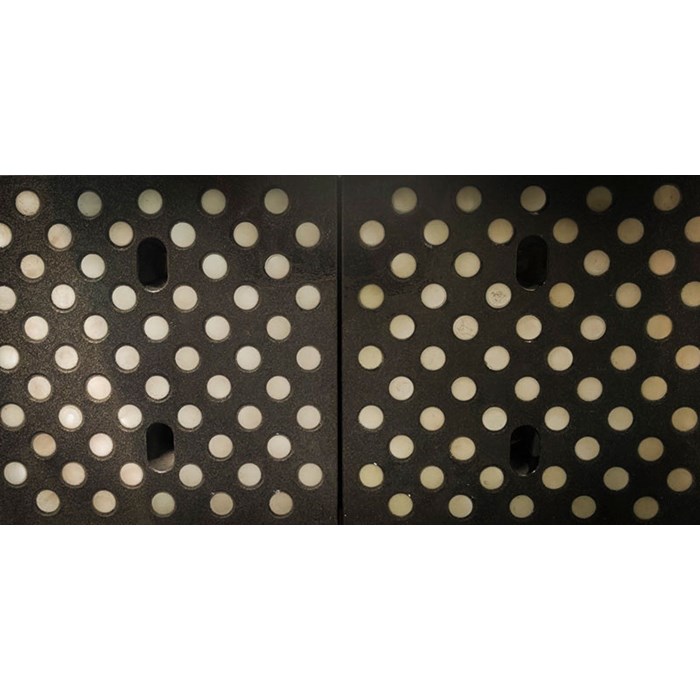

Anti-wash liner system designed to eliminate joint wash generated by using square liners. Available in horizontal, vertical and double-sided designs in a wide range of sizes and materials.

Liner design effectively captures fine material that acts as a protective layer. Rock-on-rock wear results in very little wear on the lining itself, making it long-lasting and sustainable.

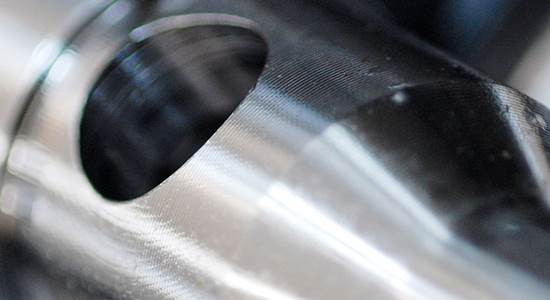

Xalloy™ wear linings are bimetallic sheeting solutions, which offer resistance to extreme abrasion and also some impact. Xalloy™ wear linings are manufactured using state-of-the-art welding technology to apply a highly alloyed chromium carbide-based material to a mild steel backing plate.

Tough modular liner system and the ultimate choice for situations where equipment can only be accessed from the inside. Available in a range of material options to suit the application, including cast metallic options, rubber and ceramic products.

Can be manufactured in a range of alloys designed to suit the intended application. From high hardness white irons offering high abrasion resistance to manganese steels offering impact toughness, there is metallic cast liner product to suit any application.

Metal matrix composite wear liners provide an innovative ultra-wear resistant material by combining the very high hardness materials imbedded within high hardness chrome cast iron matrices. The composite design provides the combined benefits for lower cost-per-ton of material processed.