Benefits

No need for workers to be inside the mill

Fewer parts and a unique attachment system speed up installations by up to 40%

Liners optimized for your specific mill

High-performing parts improve efficiency, and long-lasting parts mean fewer parts are needed

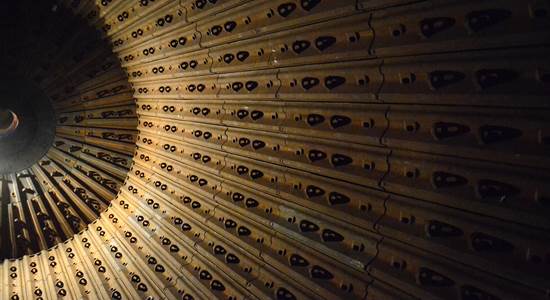

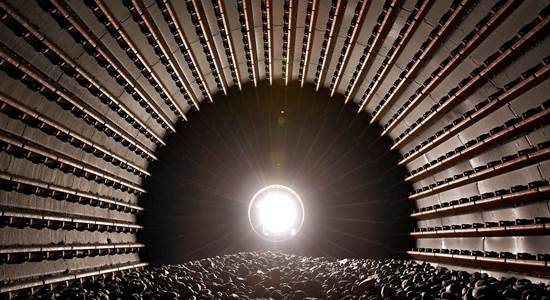

A Megaliner™ element integrates multiple lifter and plate rows and has a minimum number of attachment points. In some cases, the lining consists of up to 80% fewer parts. It covers a large area of up to 8 m² and is light-weight in relation to size. Being several times larger than a traditional lining enables much faster installations.

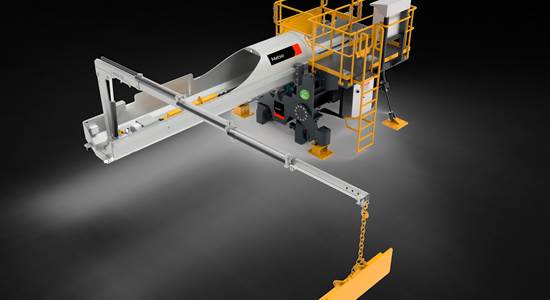

With Metso’s unique attachment system, liner bolts are inserted and removed from the outside of the mill. So, there is no need for any member of the installation crew to be in the danger-zone of the liners while inserting or removing liner bolts. The liner handler operator can simply position the liners acting alone. Moreover, the workers can stand on a steady platform outside the mill when tightening the bolts which enables a better working position and working environment.

Megaliner attachment system, with minimum number of attachments points, also helps to speed up removal of used liners. Having the bolts attached from the outside of the mill means that they are well protected from dust and wear and therefore easier to remove. Old liners can easily be stripped out by the liner handler operator. A tool for taking out the first row is available. Thereafter, gravity is generally enough to remove the liners.

Metso's patented Liner Positioning System uses camera technology to speed up mill liner installations even further and reduce the risk of accidents. The technology, in combination with guiding markers, gives the liner handler operator full control of the process and increases safety for installation crews while also improving mill uptime.

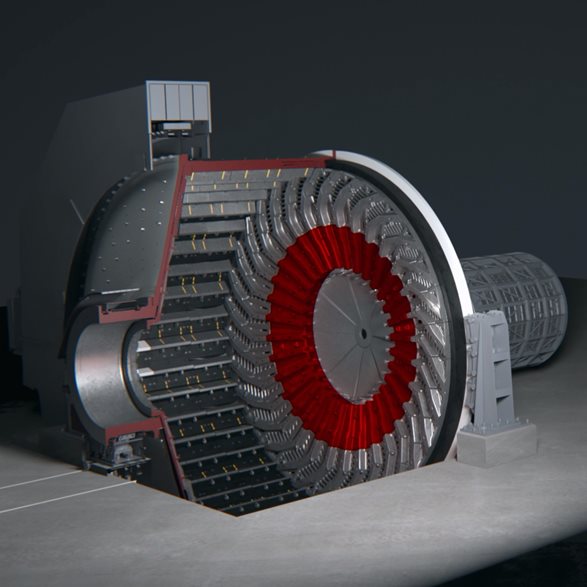

Now available for your entire mill

Megaliner™ is now available for all sections of horizontal mills: the head, the shell and the discharge system.

Read more about Megaliner for discharge systems

Speeding up mill relines at Kevitsa

Metso offers mill linings with materials and designs optimized for each specific application. We work closely with our customers and carefully follow their process to make sure the lining we supply is always optimized for current operating conditions. We can design and supply mill linings for all types of mills - for Metso mills as well as for competitor mills - and for all parts in the mill. Our wide product range, innovations, knowledge and experience make us unique. Our approach to lining design is focused on grinding performance, mill uptime and safety/sustainability.

Services for grinding

Discover our wide range of mill lining materials. Our ability to combine different materials in the same mill, using each material where it performs the best, enables us to optimize your grinding process, and make it more sustainable.