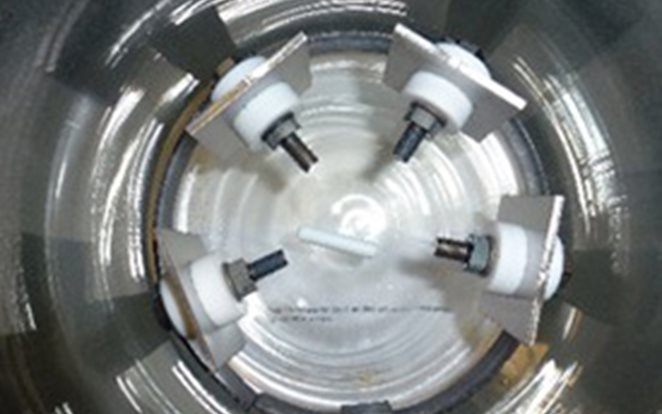

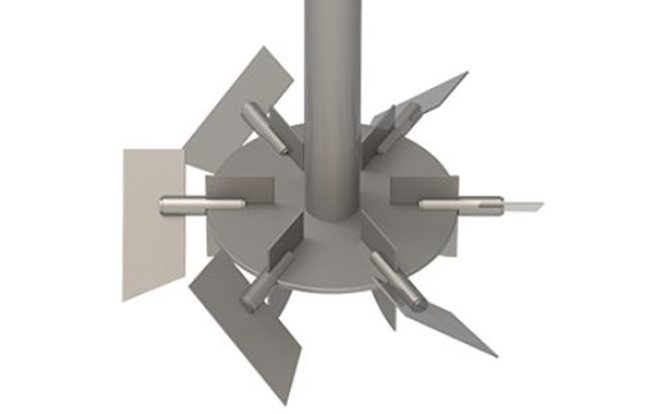

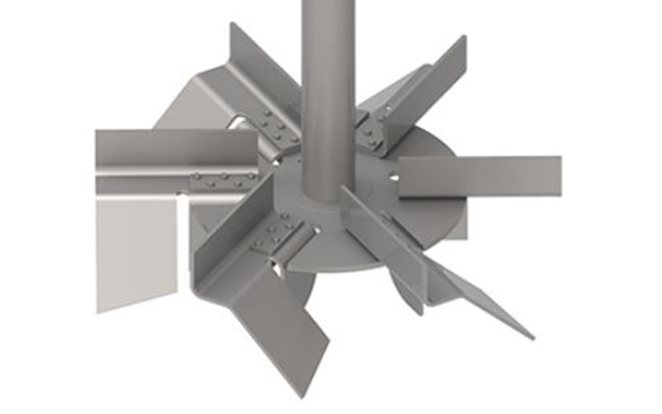

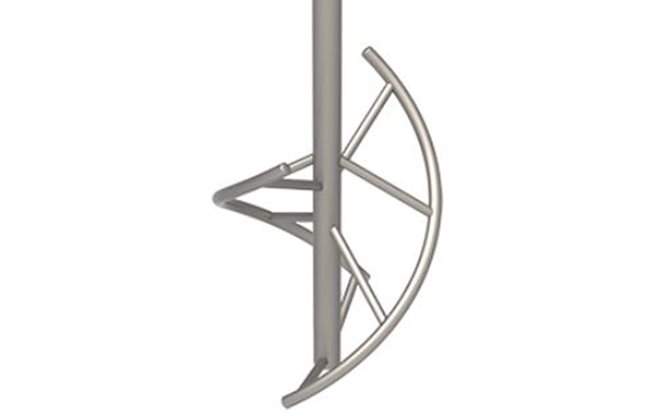

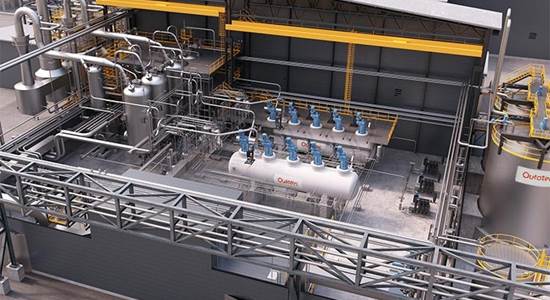

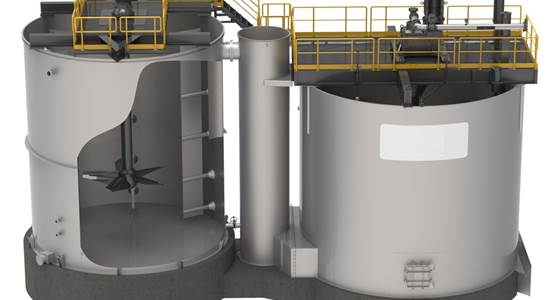

The Metso OKTOP® Agitators enable reliable and efficient operation in demanding mining, minerals processing and metallurgy applications. Agitators are used in various mixing, solids suspension and gas dispersion duties and are used in both in atmospheric reactors and autoclaves. References range from Conditioners and filter feed tanks to CIL, CIP, BIOX, strong acid leach and precipitation reactors. Currently Metso agitators have over 600 references around the globe in very diverse applications.

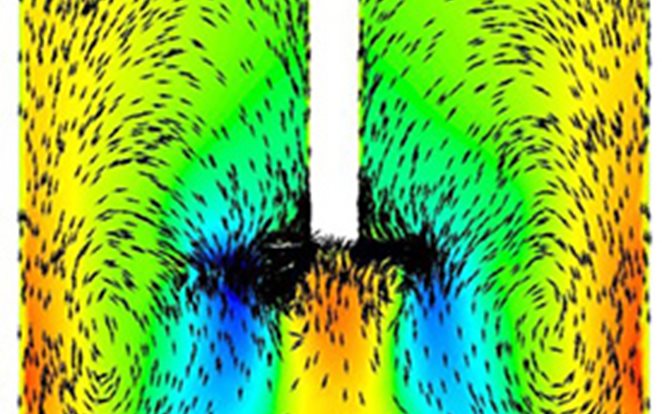

The agitator design and selection is based on our long history of operation on plants and wide range of research in the Metso research center in Pori, Finland. In Pori we can perform process kinetics, solids suspension, gas dispersion and materials testing for the agitators. We have readily available very experienced CFD experts and CFD is used extensively in product development.