Features

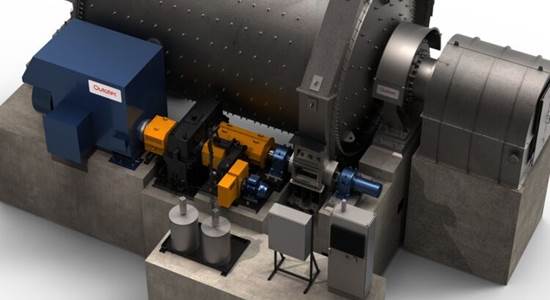

With systematic monitoring of condition parameters, you are able to detect problems, follow-up on any abnormal symptoms, and track trends of failure processes. The necessary parameters are acquired using mechanical, electrical, and other measurement methods. This data is gathered during site visits with hand-held devices, or remotely using on-line data measured with fixed sensors and systems installed in your equipment.

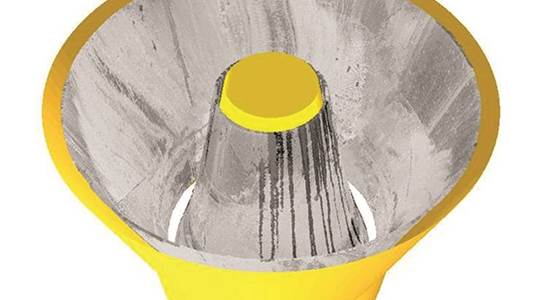

Measurement and follow-up parameters are defined based on the technical characteristics of the machine and its probable failures. Metso expert analysts provide detailed analyses that provide information for the diagnosis, prognosis, and the required maintenance actions. In addition, we offer inspections during operation and shutdown to support condition monitoring measurements and the elimination of conditions promoting failures.

- Tailored measurement methods and condition parameters based on probable failures and problems

- Condition information derived from periodic measurements and inspections performed onsite

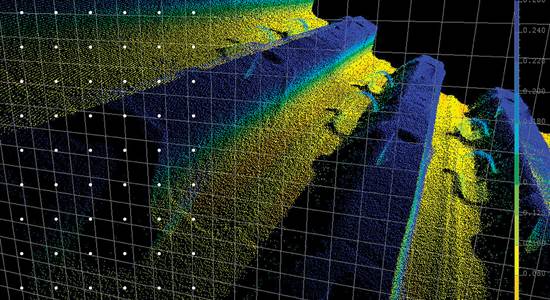

- Remote monitoring conducted through equipment sensors and connected to the monitoring system via the internet

- Expert analysis and reports, including recommendations based on condition data

- Continuous development of condition monitoring activities

Scope

- Condition monitoring systems and services for contract period

- Expert support for operation and maintenance activities

- Condition monitoring is available on one machine or several, or on partial processes spanning the whole site