Our sustainability agenda

Our climate impacts

Our purpose is to “Enable sustainable modern life.” Climate change is one of the biggest global challenges, and a topic where Metso can play a significant role together with our customers. Therefore a large part of our sustainability focus is on climate change.

For the global warming to stay within 1.5 degrees, the world needs to get to zero emissions by 2050. Reaching global climate targets requires significant decrease in CO2 emissions by increasing the use of renewable energy sources and production efficiencies. Energy transition requires large investments into renewable energy generation, downstream power emissions, battery technologies and electric vehicles. This such as copper, nickel, lithium and other rare earth metals.

Meeting this demand will require significant growth in minerals production. Metso offers sustainable technologies that support its customers’ energy transition plans. As a leading supplier of equipment and services and given how energy intensive rock comminution and processing is, our approach to technology and innovation really matters. Central to our sustainability efforts is our Planet Positive offering. These products are more energy and/or water efficient than the benchmark technology.

In addition, our target is to reduce our own CO2 emissions to reach net zero by 2030. We are also aiming to reduce CO2 emissions by 20% in logistics by 2025 and targeting that 30% of the supplier spend by the end of 2025 is with partners who have also set a science based emission target. Baseline year for all the targets is 2019.

Annual report 2023 has been published

Introducing Metso in battery minerals

We are driving a more sustainable energy transition with our comprehensive coverage of the battery minerals production and recycling processes. The growing adoption of electric vehicles is driving rapidly increasing demand for rechargeable batteries and their input commodities - including lithium, cobalt, nickel, graphite, manganese, copper and aluminum.

We have a holistic insight into the battery minerals segment, stemming from a comprehensive technological coverage of the entire value chain. From providing new exploration and greenfield sites with equipment and practices, to helping improve the efficiency of existing brownfield mining and extraction sites, plants and processes, we have also developed efficient and responsible processes for recycling minerals from decommissioned batteries. Tomorrow’s battery mineral processes not only need to be more sustainable, but also more transparent, safe and reliable.

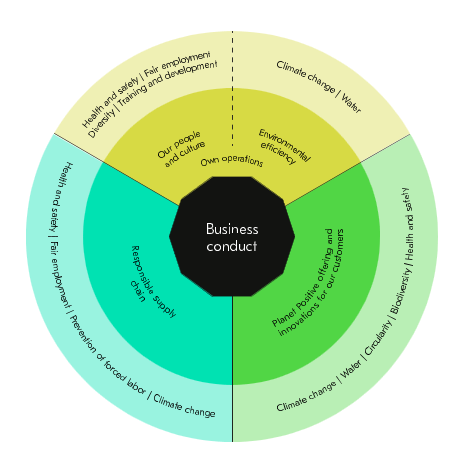

Planet Positive - our approach to sustainability

Responding to the climate change challenge is collaboration between companies and countries. That’s why we must act together with our customers and partners in developing the energy and carbon efficient technologies that support the energy transition. Together, we can create a better future. We are the partner for positive change.

Central to our sustainability efforts is our Planet Positive offering – products and services that are significantly more energy- or water-efficient than an industry benchmark or a previous-generation product in the market. Planet Positive products help our customers cut their CO2 emissions, both directly and through reductions in the carbon intensity of manufacturing and delivering products, as well as by offering the potential for increased recycling.

Planet Positive services on the other hand can improve our customers’ processes with modernizations and upgrades, as well as by optimizing existing production processes. Our services help our customers make incremental improvements, progressively accumulating benefits over the lifetime of the equipment. In the long run, such cumulative gains can be very significant.

Our Planet Positive portfolio already includes over 100 products, and we aim to keep expanding and improving this offering to have a Planet Positive product for every part of our customers’ value chain. To achieve this, all our R&D projects must have sustainability benefits; we aim to have 80% of our R&D spend on Planet Positive product and services offering development by 2030.

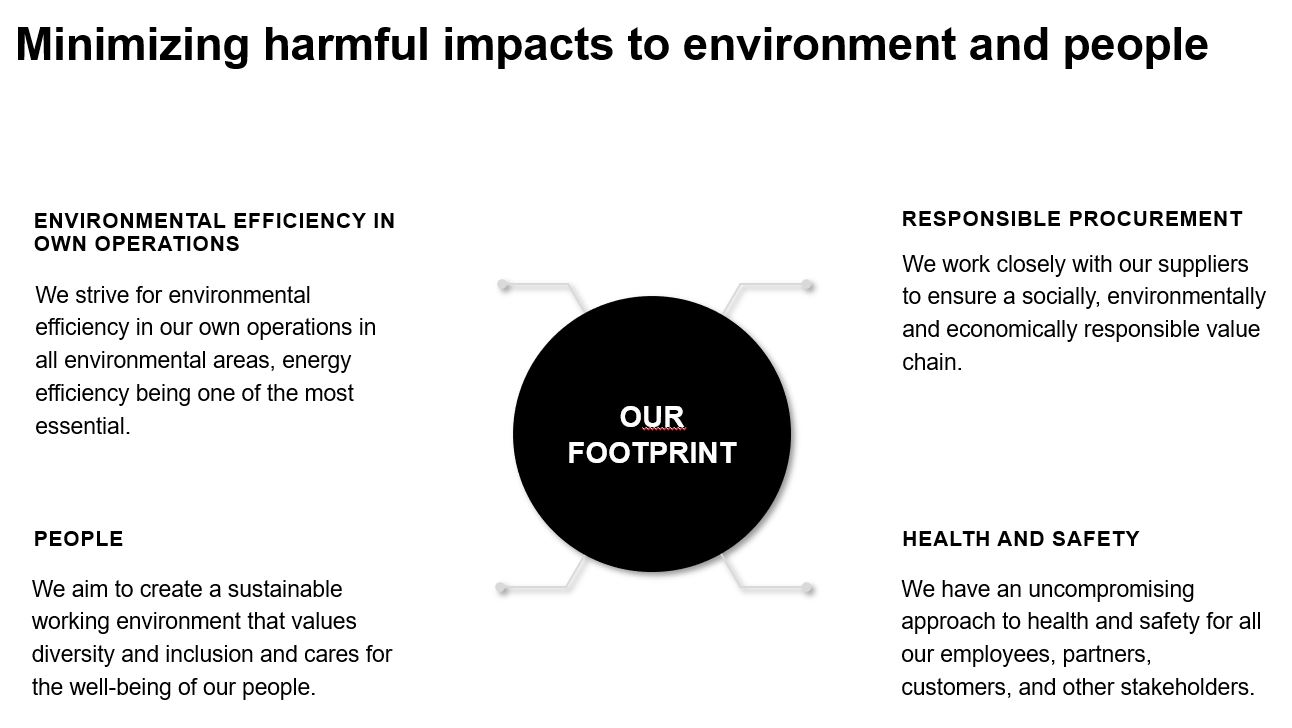

Our footprint

Our footprint means the environmental impact we generate when producing the goods and services and delivering them to the customer. We aim to minimize any harmful impacts to the environment, people in our own operations, as well as logistics and supply chain. We actively collaborate with our suppliers and partners to create more sustainable value chain from raw materials to finished product. Safety is our number one priority, both in our own operations and in the manufacturing and use of our products.