End-to-end solutions for battery minerals extraction, refinement, and recycling processes

Digital tools (Geminex™) for adapting operations based on variability in ore bodies

Proprietary technology with broad industry know-how and delivery capabilities

Key drivers for battery minerals industry

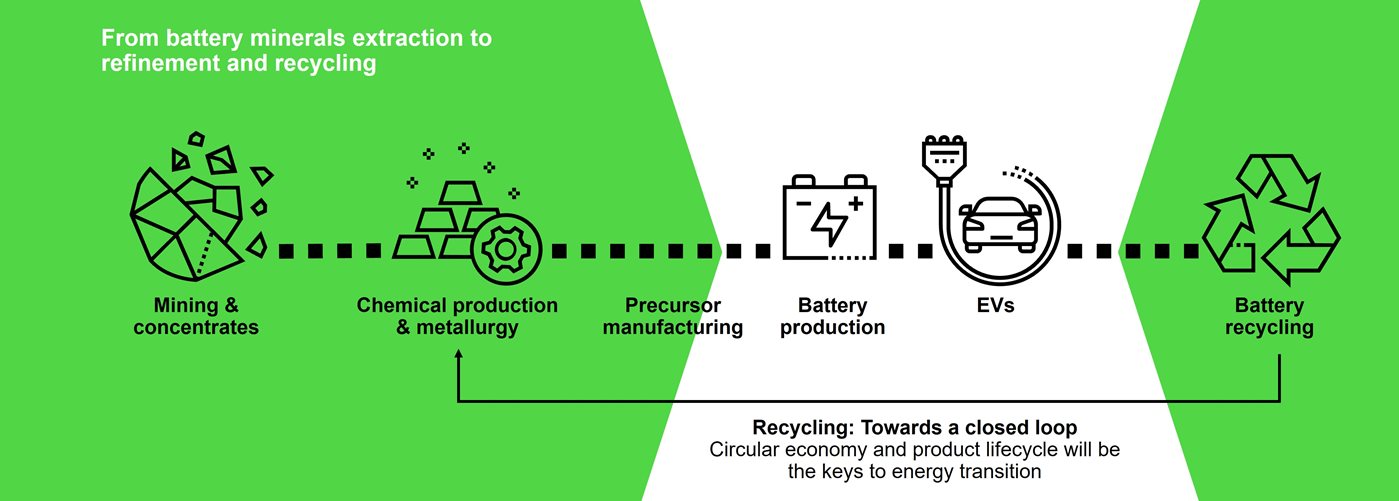

The growing adoption of electric vehicles is driving rapidly increasing demand for rechargeable batteries and their input commodities - including lithium, cobalt, nickel, graphite, manganese, copper and aluminum.

As society continues to embrace batteries as the more responsible alternative for burning fossil fuels, we need to accept that we can’t just concentrate on the sustainability of individual end user commodities such as EVs. To determine and improve sustainable performance, we need to take a holistic approach and lead the way towards a more responsible overall business ecosystem.

Introducing Metso in Battery Minerals

Multiple minerals and processes

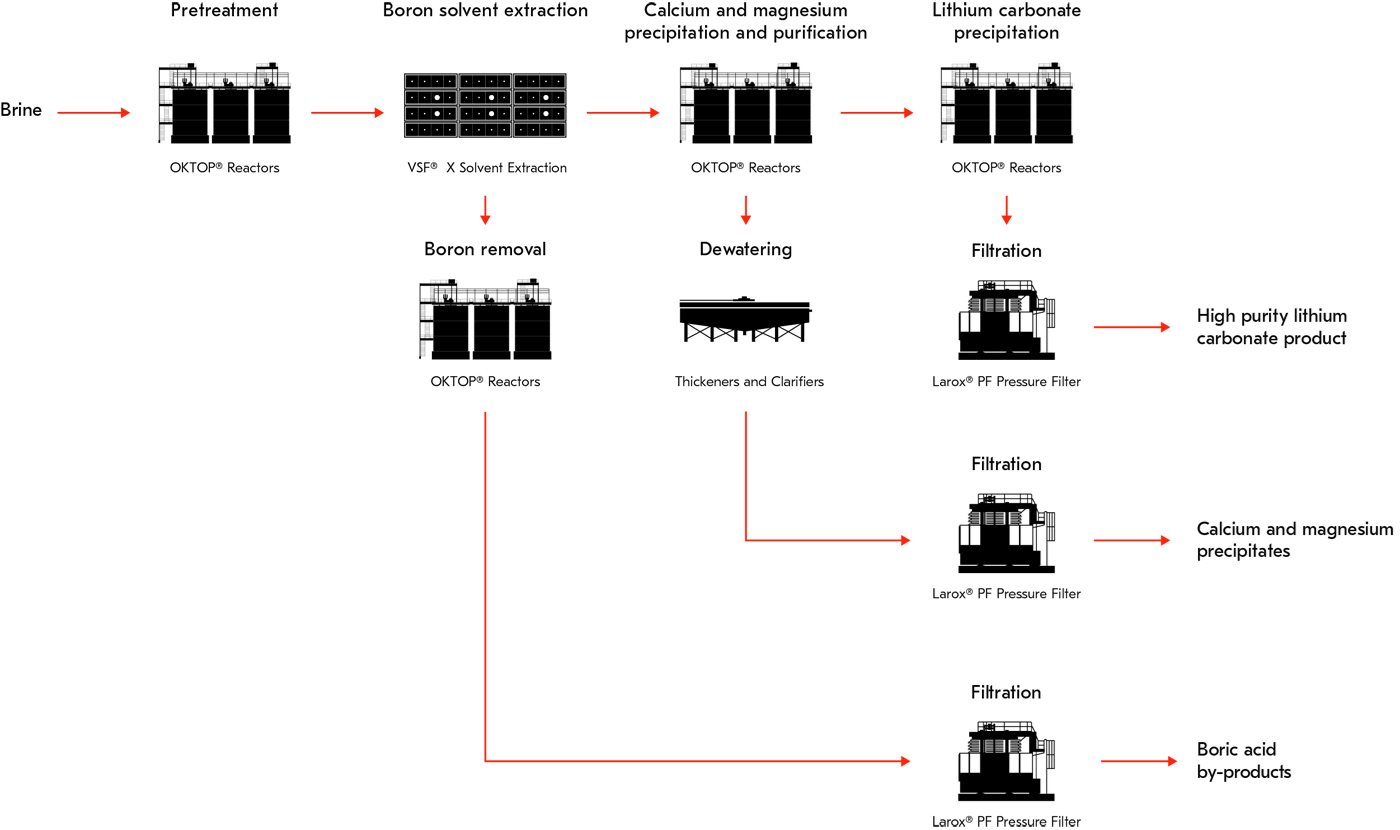

Brines – Hydrometallurgical processing

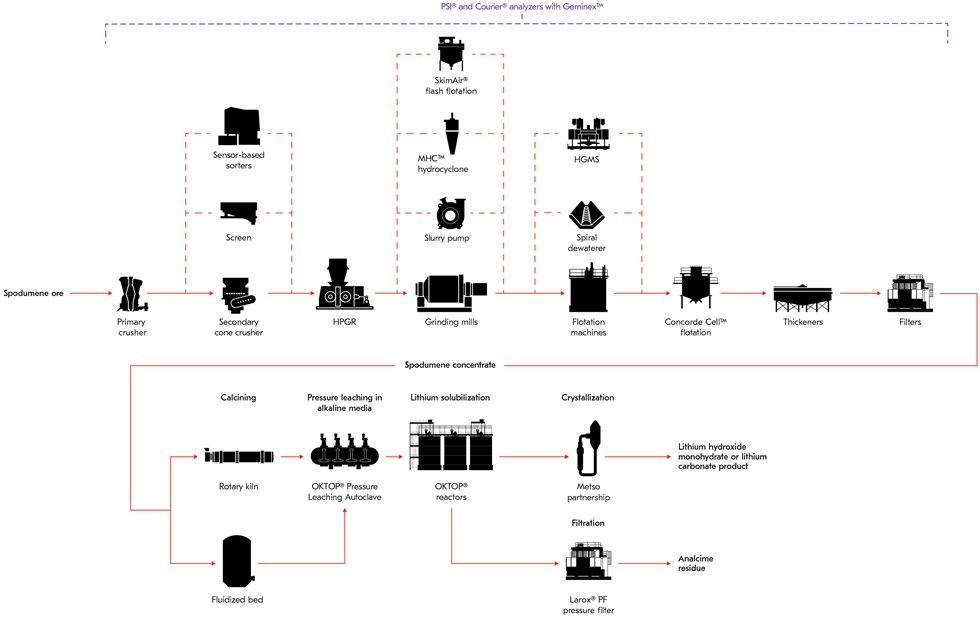

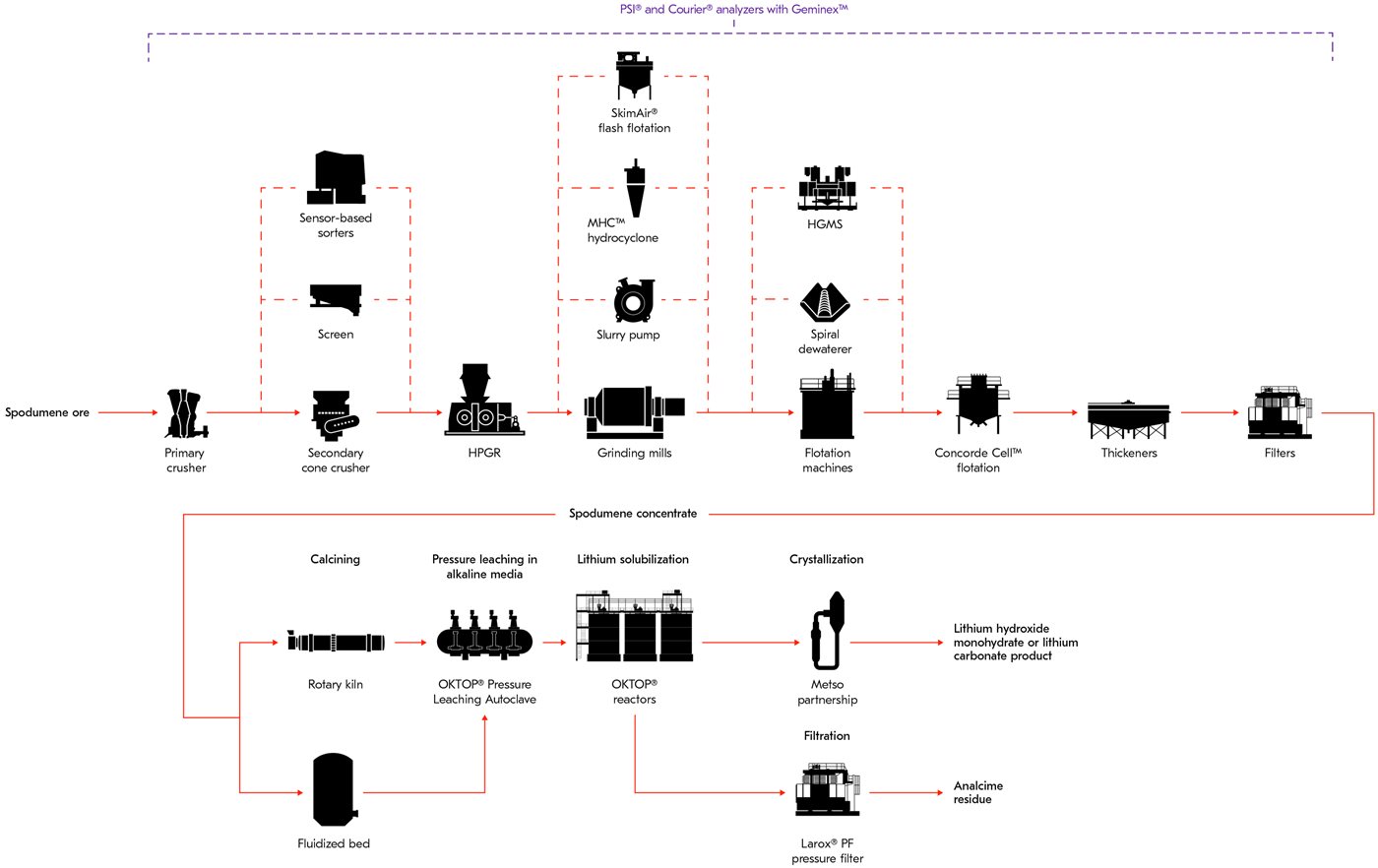

Spodumene – Concentrator plant and hydrometallurgical LiOH process

Metso provides the path to optimized solutions and complete plants for the production of high-purity lithium salts. Our innovative and proven calcination, leaching, purification and lithium recovery technologies cover the whole range of production, from raw materials to battery grade lithium products: most importantly Lithium Hydroxide Monohydrate and Lithium Carbonate.

Metso’s proprietary technology offers a short-cut process concept for spodumene concentrates: direct alkaline leach process for lithium extraction and solubilization, followed by crystallization of the lithium salt product. Furthermore, the leach process is environmentally sustainable: acid & sulphate free, without undesired crystallized salts or by-products, producing inert & neutral mineral residue for re-use or disposal.

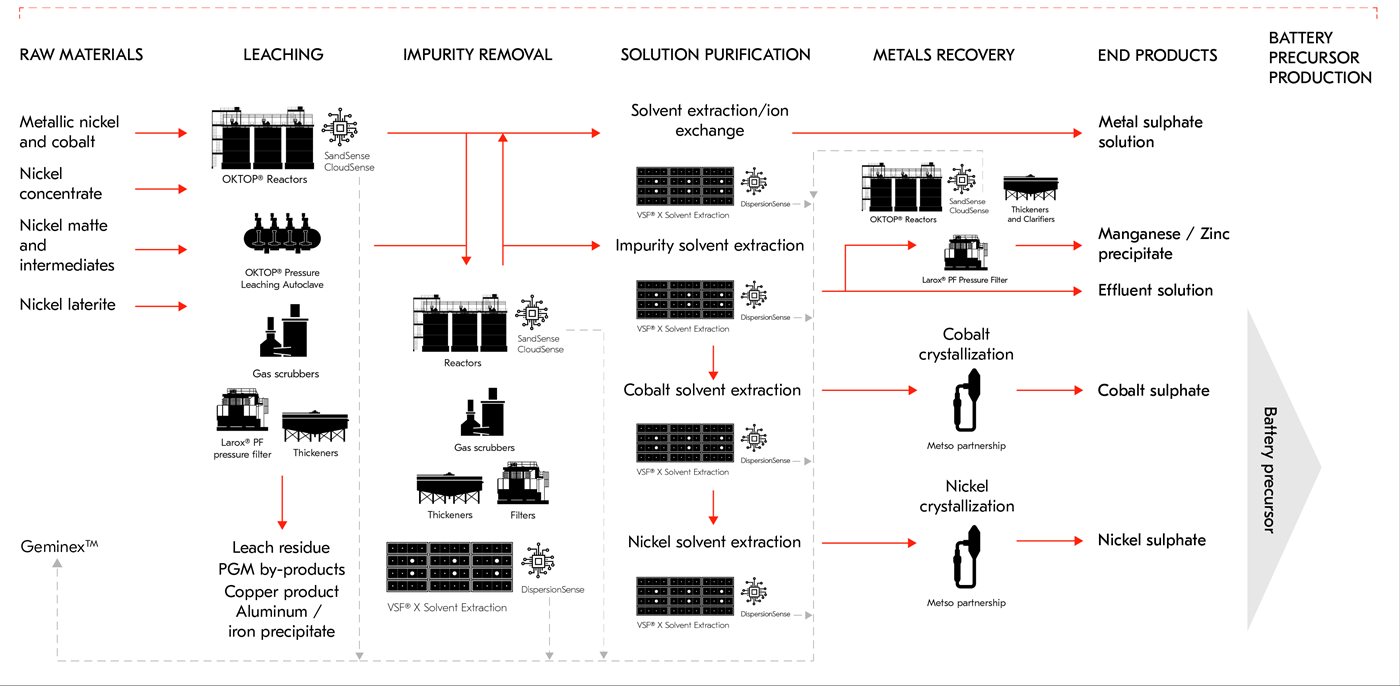

Nickel and Cobalt - hydrometallurgical processing

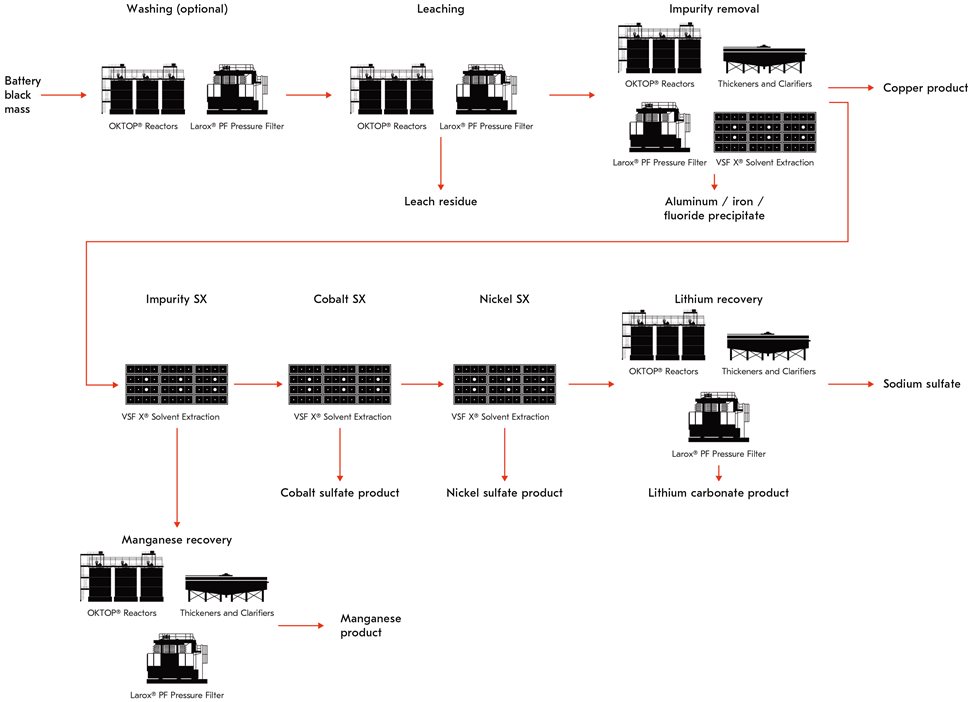

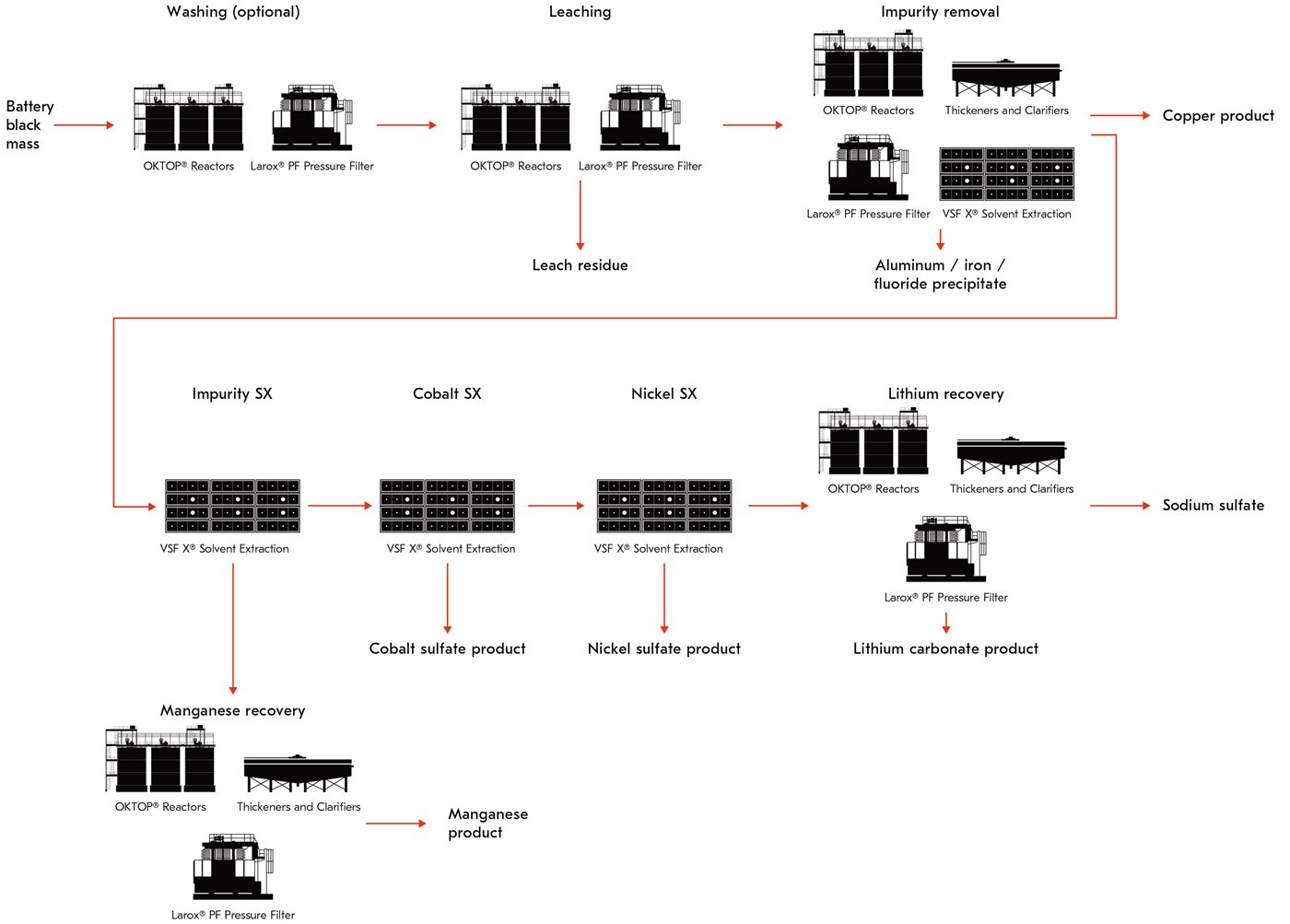

Black mass - Battery recycling process

The Battery black mass recycling process treats batteries after mechanical separation and optional thermal treatment for the recovery of nickel, cobalt and lithium, as well as optionally manganese and copper. The process flowsheet can also be tailored according to the feed materials and desired end products with possible phased approach, starting with recovering the most valuable metals.